Search

The Renewable Energy site for Do-It-Yourselfers

Pump and Pipe

Sizing for a Solar Water/Space Heating System

| This section covers the sizing of the collector circulation pump and

the pipe diameters for a solar space or water heating system.

The example worked out below is for a drainback system, but the comments

at the end explain what adjustments to make for a closed loop system

with antifreeze.

| |

Disclaimer

I'm not a plumber or solar professional --

I can't even be trusted to

fill the dog's food bowl.

So, use this material at your own risk -- I take no responsibility

whatever for its correctness

As always -- do your homework! |

|

|

|

Overview of Sizing the Plumbing and Pump for Solar Collectors

The basic underlying requirement is that you want a pump and plumbing system

that will push enough heat transfer fluid (typically water) through your solar

collectors to efficiently remove the heat that the sun is depositing in them.

Too little flow, and the collectors will run hotter and less efficiently, too

much flow and you are wasting money on bigger pipes and pumps than the system

needs, and using more pump power than you need to.

The steps involved in the pump and plumbing sizing:

- Calculate the flow that the collectors need

- Measure the vertical distance between the top of the collector and the

tank water level

- Calculate the pressure drop and flow velocity for the plumbing system.

- Pick a pump that provides 1) the flow estimated in step 1, 2) the

vertical lift calculated in step 2, and 3) can handle the pressure drop

calculated in step 3.

The Example

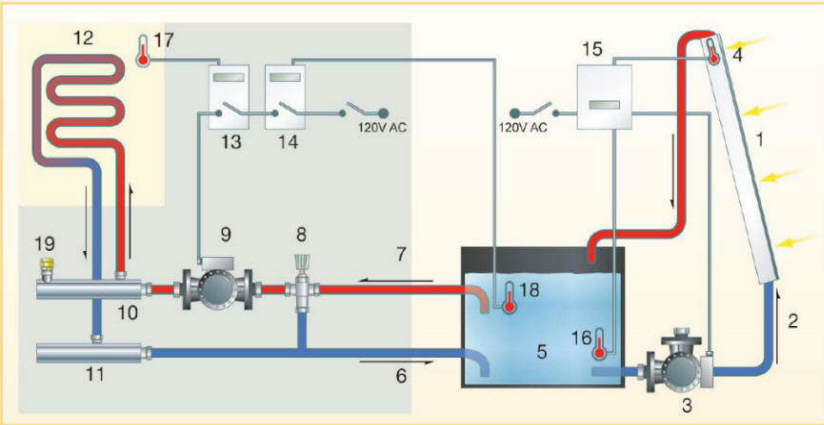

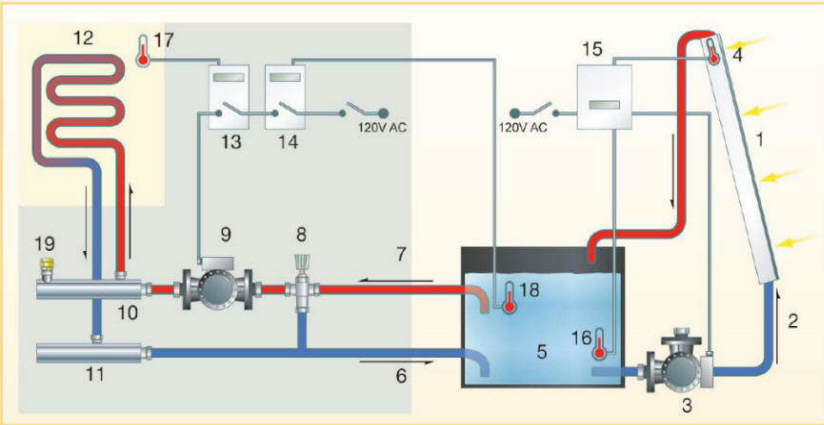

I will use my Solar Shed project as an example. Its shown in detail

here....

In a nutshell, it has 6 collectors of 40 sqft each. The collectors have

half inch vertical risers tubes (about 9 per collector), and 1 inch top and

bottom manifolds. The collectors are placed side by side with the

manifolds connected together. From a flow point of view, this puts all the

collectors in parallel. All the details are shown

here....

Water is pumped from a storage tank just behind and below the collectors to

the lower manifold on the right most collector.

Water returns from the bank of collectors to the tank via the upper manifold

on the left most collector.

On the Solar Shed, all the plumbing runs are very short, so I'll make the

example a little more realistic by saying that the tank is another 20 ft away

from the collector -- this will lengthen the supply are return pipes and number

of fittings to more realistic values.

The example covers sizing the pump (3), and the supply and return lines to the

collector (1).

This is a drainback system, meaning that the when the pump is not operating,

all of the fluid in the collector and plumbing system drains back into the

storage tank by gravity. This provides the freeze protection for the

system, and means that plain water without antifreeze can be used.

At the end of the example, I'll briefly cover what the changes would be to do

the pump and pipe sizing for a closed loop system with antifreeze.

Step 1: Calculate the Flow to the Collectors

The collectors need to have sufficient flow to remove the heat from the

collector under sunny conditions. This flow rate can be calculated knowing

the solar heat input to the collector and collector efficiency, but its easier

to just use the manufacturers recommendation. Since my collectors are

homemade, I will use the recommendations for a similar commercial flat plate

collector. Heliodyne makes a series of similar flat plate collectors, and

recommends that the flow rate be between 0.025 and 0.075 gpm per sqft of

collector. You can probably guess from this wide range that its not

critical to hit some particular flow rate -- anywhere in this wide range is OK.

If you want to see the actual

loss in efficiency and heat output from the collector as you reduce flow rate,

look here...

So, lets try for the middle of the range at 0.04 gpm per sqft of collector.

The target flow rate the is:

Target Flow Rate = (240 sqft)(0.04 gpm/sqft) = 9.6 gpm

So, about 10 gpm flow to the whole collector array. Note that the flow

could be anywhere from 6 gpm up to 18 gpm and still be in the recommended range.

Just as a side note, 6 collectors is about the maximum number of collectors

that you want to connect in parallel this way. If too many collectors are

connected in parallel, the flow to all of the collectors will not be even.

For larger numbers of collectors, the collectors can be divided into banks of

parallel connected collectors.

Step 2: Measure the Pump Vertical Head Requirement

For a drainback system, when the sun comes on the collectors, the controller

will turn the pump on, and the pump must be able to pump water all the way up to

the top of the collector to start the flow. In order to make sure the pump

can do this, you must carefully measure the VERTICAL distance between the water

level in the tank, and the top of the collector. If the top of the

collector is 30 ft over and 11 ft up from the tank water level, the number you

want is the 11 ft -- this is the vertical distance from water level to top of

collector. Measure this carefully -- don't eyeball it. Note that you

measure from the water surface level in the tank, not from the pump level.

This requirement at startup to pump water from the tank all the way to the

top of the collector is a tough requirement for pumps, and it will likely be the

main consideration in picking the pump to use.

For the my Solar Shed system, the vertical distance from the water level in

the tank to the top of the collector is 11 feet 3 inches.

So, the pump must be capable of pushing water up at least this vertical

distance. Some margin should be allowed about the vertical distance.

In other words, don't choose a pump that just barely has enough static head to

make the top of the collectors. People vary on how much margin should be

added, but Alan R.ushforth,

who has done a number of drainback systems and has had experience with pumps

that don't quite get the flow started recommends that the pump have a static

head capability that is 20 to 30% greater than the vertical distance from tank

water level to the top of collector. I would use that

recommendation.

So, for the Solar Shed, the minimum pump static head would (11.25ft)(1.25) =

14 ft of static (startup) head.

Once flow is well established, and the return line is running full, the only pressure that the pump has to

overcome is the friction losses in the pipe -- that's what the next step is

about.

Step 3: Calculate the Pressure Drop in the Plumbing

| In this step, we will guess pipe sizes, and

then calculate the total pressure drop through the system for: 1) the

collectors, 2) the supply and return pipes and the fittings in these

pipes, and 3) any valves or other pressure drop causing components.

With the trial pipe sizes, we look up the flow velocity and pressure

drop. If the velocity is too high, or pressure drops larger than a

reasonable pump handle, then we up the pipe diameter and try again. |

Pressure Units

You will find several units used to express pressure drop in pipes and

in pump specs. Here is how to convert between them:

1 psi = 2.3 ft of water = 27.6 in of water =

6894 Pa

1 ft of water = 12 in of water = 0.433 psi = 2985

Pa

|

We will need the lengths of the supply and return pipes, and the number and

type of each fitting and valve. For the Solar Shed, the supply and return

lines are very short, because the tank is right below the collectors. This

is nice, but probably not typical, so I've added another 20 ft to each and a few

extra fittings.

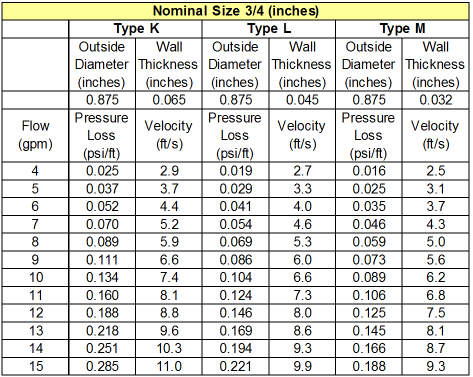

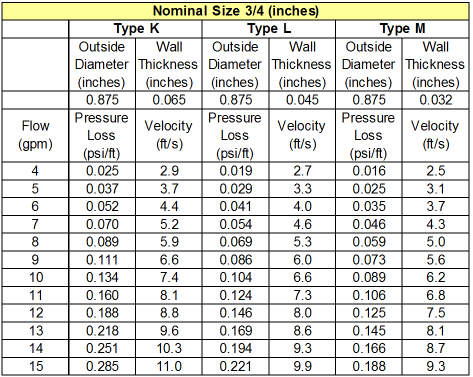

Lets try adding up the system pipe pressure drop with 10 gpm flow and 3/4

inch supply and return pipes. The system uses type M copper pipe (this is

the thinner wall pipe commonly sold at hardware stores).

Adding up the pipe lengths and fittings for the system:

|

Item |

Supply |

Return |

| |

Qty |

Equivalent Length (ft) |

Pressure drop

(psi) |

Qty |

Equivalent Length (ft) |

Pressure

Drop

(psi) |

|

Manifold (1 inch) |

12 |

12 |

0.3 |

12 |

12 |

0.3 |

|

Pipe (3/4 inch) |

28 |

28 |

2.5 |

52 |

52 |

4.6 |

|

Elbows (3/4) |

4 |

8 |

0.7 |

6 |

12 |

1.1 |

|

Couplings (3/4) |

2 |

0 |

0 |

2 |

0 |

0 |

|

Valves (3/4) |

0 |

0 |

0 |

1 |

0 |

0 |

|

Total |

|

|

3.5 |

|

|

6.0 |

Build a little table like the one above to record and sum up the pressure

drop numbers.

Pipe Pressure Losses

Using the numbers from the table above, we will sum up the pressure drops for

the supply and return piping and all of the fittings and valves.

| To get the pressure drop for the 28 ft of 3/4 inch

supply plumbing at the 10 gpm flow rate, look up the loss per foot at 10

gpm for 3/4 inch type M pipe. From the table at the right, this is

0.089 psi per foot of pipe. So, 28 ft would be (28 ft)(0.089

psi/ft) = 2.5 psi. Note also the flow velocity of 6.2 ft/sec.

Velocities between 5 and 8 ft/sec are considered marginally high.

Velocities over 8 ft/sec should not be allowed -- if you get a velocity

over 8 ft/sec the tube diameter is too small.

Do the same lookup for the 1 inch diameter collector manifolds using

the 1 inch diameter pipe chart at the link just below. You should

get 0.025 psi per ft at 10 gpm flow rate -- this gives 0.3 psi for the

manifold drop.

Here are some pressure loss tables for the various types of pipe:

Pressure

drop for copper pipes...

PEX pipe pressure drops...

More PEX pressure drops (very complete)...

CPVC Household Plumbing Pipe dimensions and pressure drops ..

And,

CPVC

Household Plumbing Pipe dimensions and pressure drops...

(look for the "CTS" tables), or just the CPVC table here...

Industrial CPVC/PVC pipe pressure drops...

Black polyethylene pipe pressure drops...

Note that all of these

different pipe materials have different inside diameters for the same

nominal size pipe. For example, on 3/4 inch pipe, M copper is

0.811 inch ID, household CPVC is about 0.715 inch ID, Industrial CPVC is

0.824 inch ID , PEX is 0.677 inch ID, HPPE (common black poly) is 0.824

inch ID.

Big differences.

So, be sure to use a pressure drop table for the actual type of pipe you

are using. Not being careful about this can throw your pressure

drops off by nearly a factor of 2 in some cases. (1) The CPVC commonly

available in hardware stores is "copper tube sized", meaning the OD

matches copper tubing for the same nominal size -- since the wall

thickness is greater than copper pipe, this makes the ID (and pressure

drops) larger. |

|

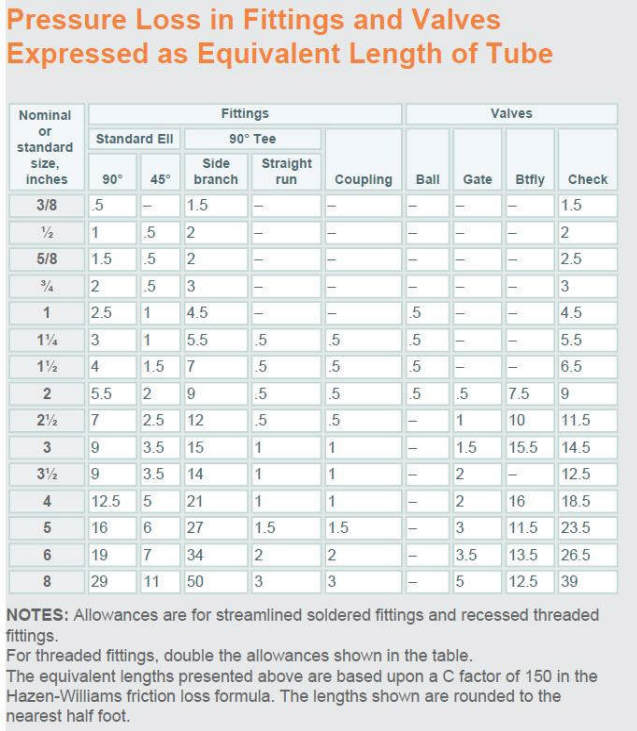

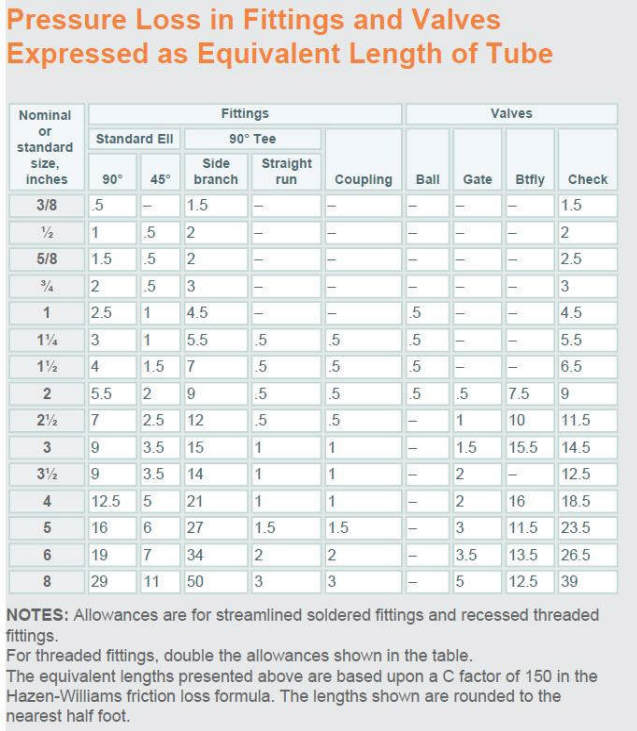

Fitting Pressure Drops

| Use the fitting equivalent length table to

the right to convert the fittings (elbows etc.) into equivalent lengths

of straight pipe. So, for the 4 elbows in the supply line, the

equivalent length of pipe is 2 ft per elbow, or 8 ft total.

Then calculate the pressure drop for this 8 ft the same you did for the

straight pipe sections -- (8 ft)(0.089 psi/ft) = 1.1 psi.

Do the same thing for the couplings and the gate valve -- which turn

out to have 0 equivalent lengths for 3/4 inch pipe.

The fittings equivalent length table is from

www.Copper.org

|

|

Evaluating the Results

Filling in all the pressure drops in the table, we get a total of 3.5 psi

loss on the supply lines and 6.0 psi loss on the return line. This gives a

total pressure drop of 9.5 psi, or 22 ft of pressure head. We also have a

velocity in the 3/4 inch lines of 6.2 ft/second, which is marginally high.

As we will discover in the pump sizing step (next) this is quite a bit of

pressure loss, and that coupled with relatively high velocity probably means we

should take a look at going up to 1 inch diameter supply and return lines -- so,

lets do that.

If you go up to 1 inch and work the pressure drops in exactly the same way,

but using the 1 inch pipe diameter table, you get this result:

|

Item |

Supply |

Return |

| |

Qty |

Equivalent Length (ft) |

Pressure drop

(psi) |

Qty |

Equivalent Length (ft) |

Pressure

Drop

(psi) |

|

Manifold (1 inch) |

12 |

12 |

0.3 |

12 |

12 |

0.3 |

|

Pipe (1 inch) |

28 |

28 |

0.7 |

52 |

52 |

1.3 |

|

Elbows (1 inch) |

4 |

10 |

0.3 |

6 |

15 |

0.4 |

|

Couplings (1 inch) |

2 |

0 |

0 |

2 |

0 |

0 |

|

Valves (1 inch) |

0 |

0 |

0 |

1 |

0 |

0 |

|

Total |

|

|

1.3 |

|

|

2.0 |

The 1 inch pipe lowers the total pressure drop from 9.5 psi down to 3.3 psi (

7.6 ft head), and it gets our 6.2 ft/sec marginally high velocity down to 3.7

ft/sec. A little bit of extra diameter makes a big difference.

| So, this is likely to be the way to go, but we will see

after the pump sizing. Another option if you did not want to go up to

the 1 inch pipe would be to lower the flow rate down toward the lower

end of the allowed flow rates. Dropping the flow rate down to the

low end of the allowed flow rate would cut the pressure drop in the 3/4

inch pipe down by about half.

|

Side Notes Why are we

ignoring the pressure drop in the collector riser tubes?

The pressure drop through the collector's riser tubes themselves is

small, and can probably be ignored. We have included the collector

manifolds above, and each riser only sees about 0.18 gpm of flow.

If you work through the pressure drop for a 10 ft long, half inch

diameter riser, its only about 0.13 inches of water head. Since

all the risers are in parallel, this is the total pressure drop over the

risers.

On the other hand, If you have a serpentine collector

in which a single length of pipe is wound back and forth through through

the full collector, the pressure drop will be larger and should be

included. Just as an example, if a 25 sqft serpentine collector

uses a single 50 ft length of half inch copper pipe to collect heat, the

the flow will be about (0.04 gpm/sqft)(25 sqft) = 1.0 gpm.

The pressure drop for 50 feet of half inch copper pipe (from the table

below) is about (0.007 psi/ft)(50 ft) = 0.35 psi, or about 10 inches of

water head.

Effective Manifold Length

In the above estimates, I've included only half of the

collector manifold length. The idea is that the flow is steadily

decreasing in the manifolds as each collector takes some of the flow out

of the manifold -- so, including half the length is a rough way of

accounting for this. If you have a lot of loss in the manifolds,

then you might want to do this more accurately by dividing the manifold

up into segments, each with a different flow rate.

Minimum Pipe Diameter

In drainback systems its not considered a good idea to

go to less than 3/4 inch supply and return pipes no mater what the

pressure loss in that smaller diameter pipes may not allow a full

drainback. Supply and return pipes must also be sloped

downward toward the tank, and the runs should be kept as direct as

possible |

Step 4: Pick a Pump

We need to pick a pump that provides:

- A startup vertical head of at least 14 ft determined in step 2.

- A flow rate of around 10 gpm with a plumbing friction loss of 9.5 psi if

we use 3/4 pipe, or 3.3 psi if we go up to 1 inch pipe.

You use pump curves to determine which pumps might meet those criteria.

We will use the pump curve family for the Taco HVAC circulator pumps to pick a

candidate. This series of pumps has been used for lots of solar

applications, but there are many other options

pump

options out there that you could look at...

These are the pump curves for the entire Taco "00" series circulators.

For each pump, the curves show the combination of flow rates and pressure heads

that the pump can produce.

We need a pump that can produce a startup or static head of at least 14 ft.

To find the startup head for a pump, trace its curve over to where it meets the

left vertical access -- this is the startup or static head for the pump.

For example, the 006 pump produces about 8 ft of static head -- not enough for

our 14 ft requirement.

We need a pump that produces about 10 gpm with 22 ft of head (for 3/4 inch

pipe), or 8 ft of head (for 1 inch pipe). To see how each pump does in

meeting this requirement, go vertically up the 10 gpm line, and read to the left

the pressure head that each pump can produce at the 10 gpm flow rate. For

example, a 008 pump can produce almost 8 ft of head at 10 gpm flow rate.

So, for the 3/4 inch pipes, the pumps that might make it are: (we need

14 ft startup head, and 22 ft pressure head at 10 gpm)

011 -- 30 ft of startup head, 23 ft of pressure head at 10 gpm

013 -- 34 ft of startup head, 27 ft of pressure head at 10 gpm

014 -- 22 ft of startup head, 17 ft of pressure head at 10 gpm

The 014 is a bit short on pressure head at 10 gpm, so the flow would fall at

bit below the 10 gpm, but still well within the OK range.

But, these are pretty honking big pumps with high power consumption -- lets

see how things turn out for the 1 inch pipe.

For the 1 inch diameter, the pumps that might make it are: (we need

14 ft of startup head, and 7.6 ft of pressure head at 10 gpm)

007 -- 11 ft of startup head, 7.5 ft of pressure head at 10 gpm

008 -- 15 ft of starup head, 7.8 ft of pressure head at 10 gpm

Some of the larger pumps would also easily meet the flow and pressure

requirements, but would be serious overkill.

The 007 is a bit tempting, but does not quite even make the 11.25 ft of

actual startup head let alone the 14 ft that includes the recommended 25%

margin.

Overall, I like the 008 as a good match on both flow and startup head at a

reasonable power consumption -- so that's why I picked it for the system:)

It has been doing great for 5 years.

If I were to look further into this example with an eye toward lowering the

system cost a bit and the pumping power a bit, I'd have a look at keeping the

3/4 inch pipe, and lowering the flow rate closer to the lower edge of the

acceptable range. This would save a little money on piping and also might

allow changing to a pump that uses less power. The flip side of lowering

flow rate is the the collector will run a little bit hotter, and will not be

quite as efficient. But, it does not look like any of the Taco pumps would

work for this, but a look at Grundfos or other pumps might find a good one.

There are many other pumps out there, and you want to consider things like

price, power consumption, reliability, ... -- not just the that the pump meets

the flow and pressure requirements.

Closed Loop System with Antifreeze

Closed loop system that use antifreeze for freeze protection are always

completely full of fluid, so there is no startup head requirement as there is

for drainback systems.

But, the antifreeze increases viscosity and pipe friction losses, and the

antifreeze has a lower heat capacity, so more antifreeze mix must be circulated

to transfer the same amount of heat out of the collector.

The following rough procedure to cover closed loop systems assumes a 50-50

water glycol antifreeze mix.

To do a closed loop system, use the same procedure as for the drainback

system with these changes.

- Multiply the collector flow rates calculated in step 1 by 1.15 to

account for its lower heat transfer capability -- but I would not go over

the top end 0.075 gpm/sqft.

- Skip the measurement of the vertical rise from tank to collector (step

2).

- Calculate the pressure drops of step 3 just as you would for water.

Then multiply the calculated water flow pressure drop by 1.3 to account for

the increased viscosity of the antifreeze solution.

- Size the pump in the same way you did for the drainback system, but

leave out the startup head requirement, and use the higher flow rates and

pressure drops covered in 1 and 3 just above.

Note that these correction factors (1.15 and 1.3) actually change with

temperature -- the ones I've used are for 140F with a 50/50 mix of glycol

antifreeze and water.

There could be a whole section on using antifreeze, but a couple highlights:

1) use polypropylene glycol, which is non-toxic, 2) use an antifreeze formulated

for solar systems -- it will have additives to keep it from turning into ugly

stuff that can ruin your system, 3) check the pH of the antifreeze every year,

and replace it if the pH is to low (acid) or its otherwise not looking good.

Gary June 25, 2010

Updated Aug 18, to include 25% margin on startup head.