Search

The Renewable Energy site for Do-It-Yourselfers

Kevin's Way North $1K Solar Water

Heating System

|

Kevin built a version of the

$1K Solar Water

Heating system, and provides a lot of good information on 1) how he

designed and built the system, 2) well thought out changes he made to

adapt the system to his situation, and 3) the performance of the

system.

Kevin faced some unique tank

space limits and collector placement limits -- the techniques he worked

out to adapt to these limits should be helpful to people facing similar

situations.

Kevin's system is located in

far nothern British Columbia at 55 degrees latitude, so it is a good

challenge for the system.

Thanks very much to Kevin for

taking the time to detail the project!

Kevin's system definitely shows the benefits of taking your time and

working carefully. |

|

Designing and Building the System

Kevin provides an excellent

description of the way in which he designed and built the system in this pdf:

Full design and construction details on Kevin's system... (pdf)

I really like the way Kevin did the

aluminum fins, and the heat exchanger is a very nice solution to the limited

inside dimensions of the tank.

Note also the pitching of the copper

pipe grid towards the center of the collector for good drain back. This is

essential for freeze protection.

System Performance

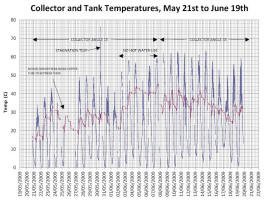

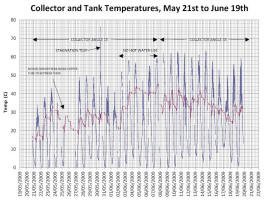

Kevin provides detailed monthly

performance plots for the periods from May 2009 to through October 2009, along

with comments on factors effecting performance, and the effect of adding an

additional collector in October.

Kevin has lots of experience in data

logging, and has set up a system to monitor and record the performance of his

system.

All the

details here...

Heat Exchanger Performance

Kevin decided to try a hybrid copper

and PEX heat exchanger. This arrangement fits his limited tank space

better than the large PEX coil that I use. The construction details are

shown in the pdf above in the Construction section.

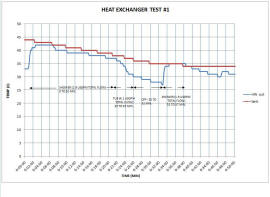

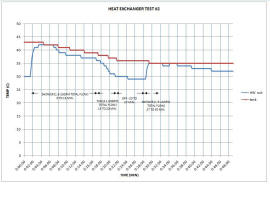

Kevin's test of the heat exchanger

performance:

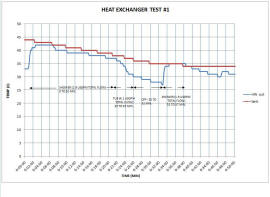

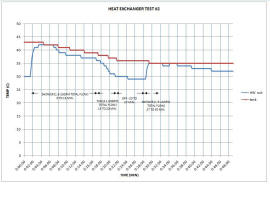

As promised, here are the two

heat exchanger tests. The pattern is very similar to yours - hot water temps

are the same as, or a degree lower than, the tank temps during the initial

emptying of the exchanger. Then the hot water temp drops in tandem with the

tank temp, staying ~2 degrees lower. At higher flows, the temp falls off,

but makes a total recovery after the rest period.

Click on images for full size

|

First heat exchanger test. |

2nd heat exchanger test. |

It appears to me that hybrid heat

exchanger gives very good performance -- about equivalent to the 300 ft coil of

PEX exchanger that I used -- so, there is more than one way to get the job done.

Data Logging System

Kevin describes the datalogging

system in the

construction pdf. Here is a little more detail on the hot water line

sensor that is pictured just below:

Not sure if these will stand

the test of time, but at $5 for a DS18B20 sensor vs. $47 for the only

waterproof commercial DS18B20 probe I could find online, the price is right.

The datalogging tank sensor is located at the same depth as the Steca one;

about 1/3 up from the tank bottom. I am logging at a 5 minute interval.

I installed a sensor on the

hot water line out from the exchanger. This is mainly to do an exchanger

test, but it also tells me when we are using hot water. I drilled a hole in

a 3/4" end cap and embedded a homemade probe in epoxy, then installed this

into a tee in the line (see photos). Don't worry about the hose clamp - just

temporary until I got a PEX clamp. So far so good.

Click on pictures for full size

|

The "1-Wire" sensor mounted

in the hot water line. |

Detail of the sensor that is

epoxyed in place. |

Final Comments

This is how Kevin sums up the size of

the job -- I think that it is a very accurate assessment:

As far as building the system,

now that it's over I don't think it was that bad :) Seriously, it's

not a trivial project, but well within the average DIYer's capabilities if a

person takes it slowly and puts some care into it. It's not one of

those "hey, build this simple system and you can be saving thousands right

away" type projects that you see being hyped these days. Maybe commercial

tanks could be used, like plastic tanks that could be insulated. This might

simplify the construction.

The bottom line is that I am harnessing the power of the sun in a cost

effective and fun way!

If you have questions about the

system, Kevin provides and email address in the Construction pdf above.

Thanks again to Kevin for doing such

a great job of documenting and testing this system!!

Gary June 26, 2009, Added performance

update November 2009