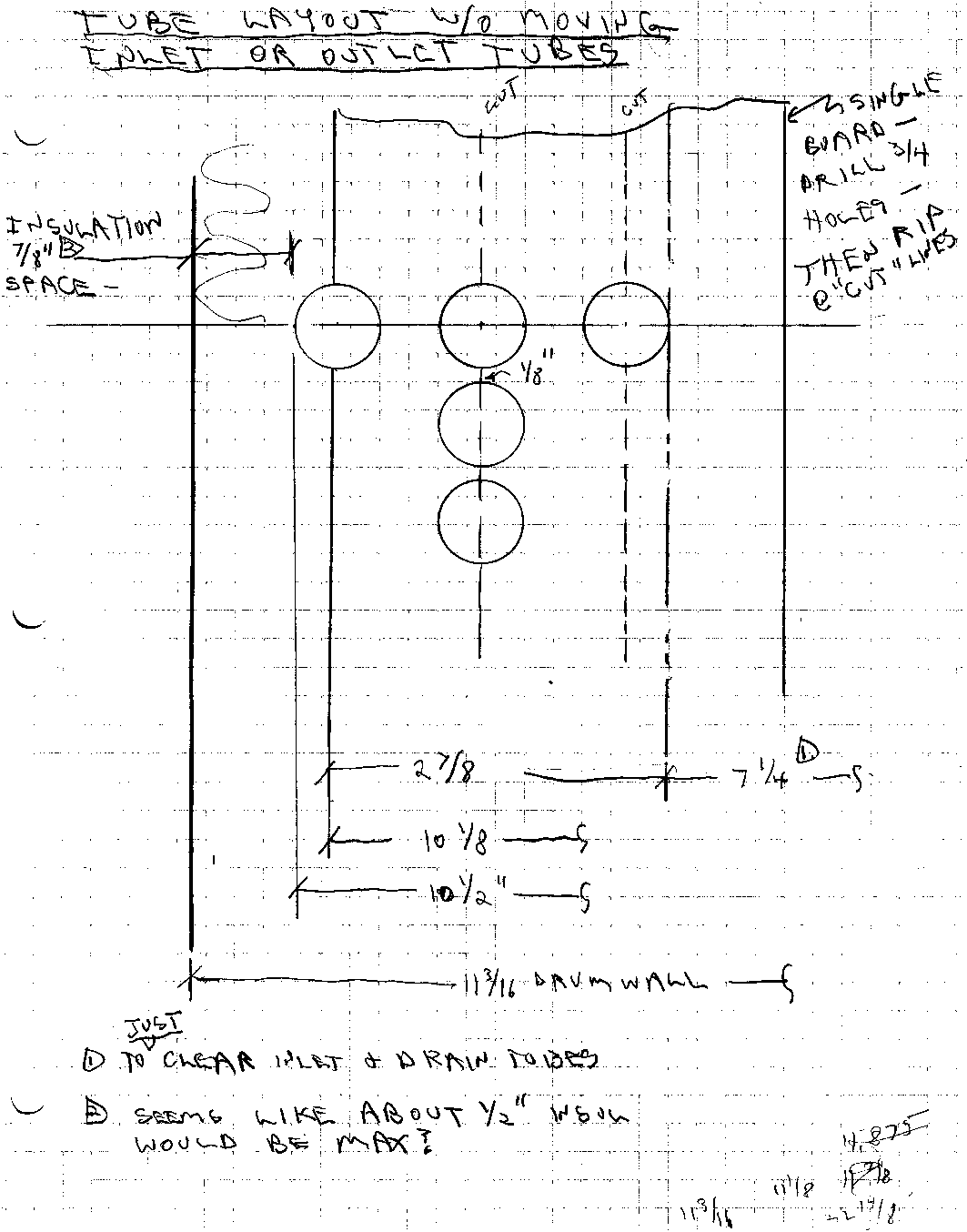

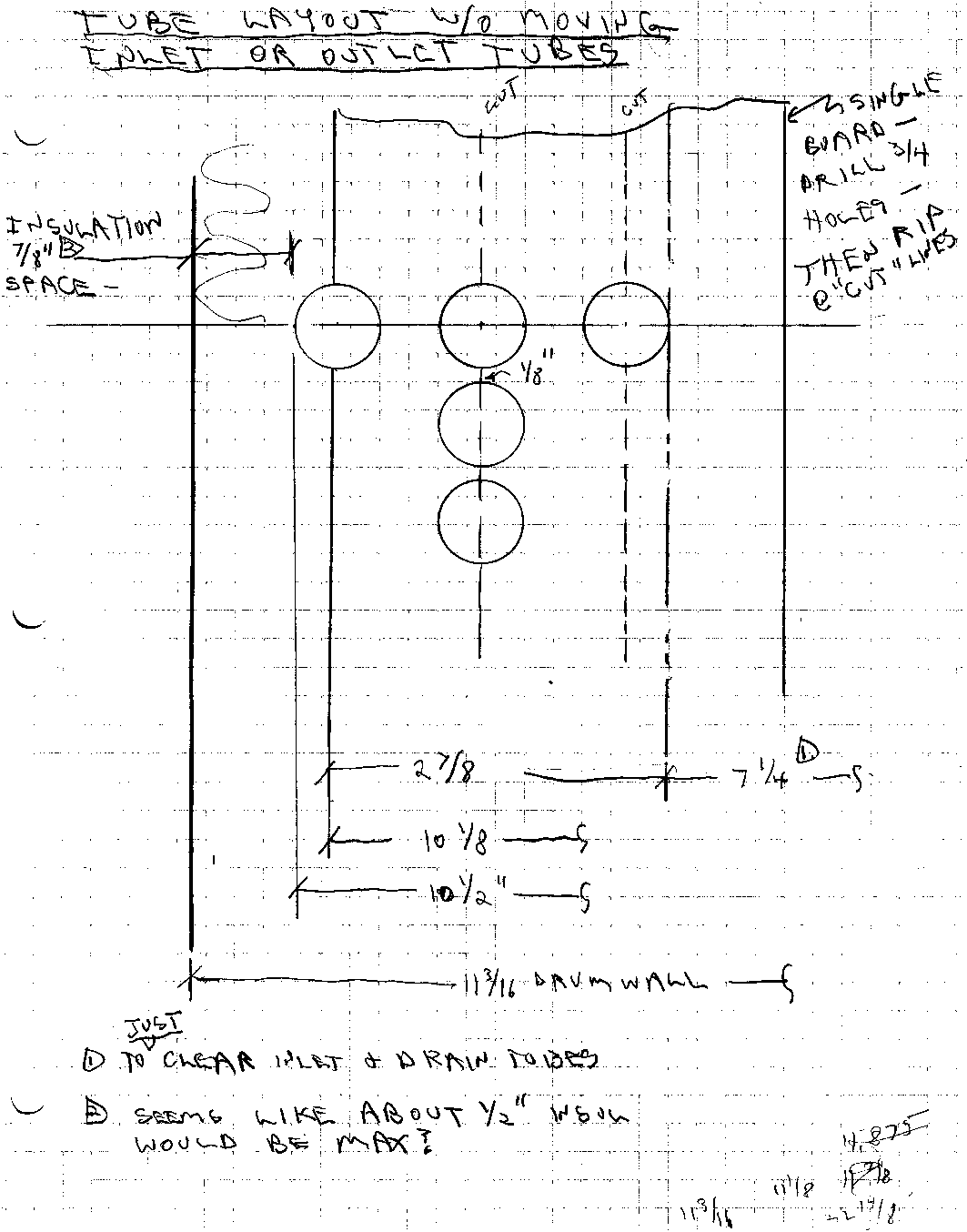

Laying out the pipe coils in the GWHX:

The sketch below shows a tentative layout for 3 coils of half inch pipe. It is constrained by:

So, you have to layout the pipe coils between an inner radius of 7 1/4 and an outer radius of about 10 1/4 inches. The layout in the sketch below shows 3 coils that (with a little adjustment) would fit the constraints.

The supports for the pipe coils would be 3 or 4 wood boards (e.g. 1X5). I would drill the 3 columns of 3/4 inch holes with about 1/8 inch of vertical spacing between the holes. Then, rip along the cut lines (there should actually be 3 cut lines -- the outer one is not marked). Then, mount the inner coil support board to my winding rig, and wind the first coil, then apply the 2nd board over this, and wind the 2nd coil, then apply the third board over this, and wind the third coil. This whole assembly could then be mounted on the drum lid. Then the supply connections made (not sure how easy that's going to be). There may be a simpler way to do the winding, but I feel pretty confident that this way will work without a lot of frustration.

On the insulation, I have in hand some of the insulation that is reflectorized, and made from about 5/16 thick poly bubble material. I could adhere this to the walls, and it would lie flat against the wall, leaving a bit more clearance for the coils to go in. Are you OK with using this for the first try? It seems like this would be enough to break the conductance path up the barrel wall, and I could just leave the outside insulation on.

In the end, maybe the inlet and outlet tubes should move closer to the center of the barrel to allow more room for pipe coils?

Let me know what you think -- Gary