Search

The Renewable Energy site for Do-It-Yourselfers

Hot Water

Recirculation Systems -- how much energy waste?

|

I wanted pass on our experience with

our hot water recirculation system, and some measurements on how much energy it

wastes.

| |

The bottom line is that the

recirculation system we inherited when we bought our current house has

cost us about $3,200 in wasted propane use over the 8 years we have had

the house!

If you have or are thinking about a recirculation system, I'd read

carefully through all the material below -- some of these systems

are very very wasteful. |

|

These systems are designed to let you get hot water instantly even at

faucets distant from the hot water tank, but they can be VERY wasteful

if not very carefully designed and implemented. |

|

Background

Homes with long plumbing runs from

the the hot water tank to the places where the water is used can have a long

wait for hot water. You turn the hot water tap on, and a minute later its

still running cold. This wastes both water and energy, and is an

inconvenience.

To overcome this problem, a water

recirculation system can be added. These systems overcome the problem by

keeping the water in the hot water supply pipe hot, so that when you turn the

tap on, you get instant hot water. There are several kinds of systems.

One type runs an extra water pipe

out to the farthest water using fixture you have. This extra pipe pipe

allows water to be circulated from the hot water tank, out through the hot

water supply pipe, and then back the extra pipe to the water heater.

In this way the water in the supply pipe is always hot.

Another type installs a crossover

between the hot and cold supply lines at the farthest water using device.

The crossover and related components allow water from the hot water tank to

be circulated out to the crossover, and then back thru the cold water line

to the hot water tank. The result is the same -- instant hot

water. This system is easier for retrofits, since you don't need to

add any pipe.

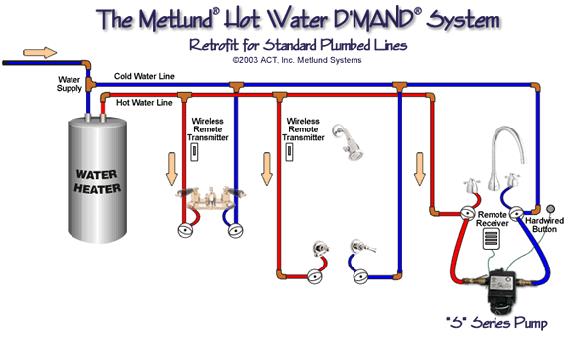

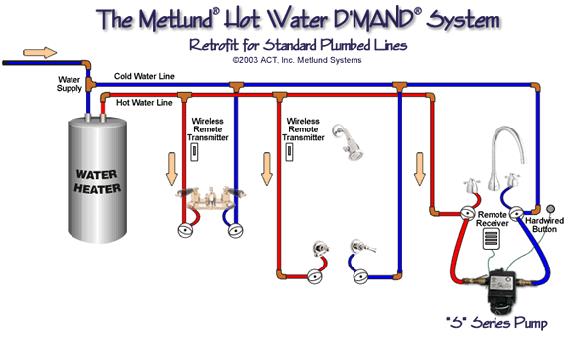

A sample system that uses the existing hot and cold water pipes

for circulation -- from the Metlund site.

Most of these systems use a pump to

circulate water, but passive circulation is also possible.

The pumps are controlled in various

ways:

They can run 24/7 (my house came

with this arrangement)

They can be on a timer so that

the pump is only running when people might want hot water.

They can be run on a thermostat

that only runs the pump when the water temperature in the pipe cools below a

certain point.

They can be set up to only run

the pump when the person who wants water "requests" it. The "request"

can be pushing a button to indicate you are going to use hot water soon, or

it can be a motion sensor that turns the pump on when people are in the

bathroom.

As you might expect, these systems

use (waste) different amounts of energy. The energy waste is of two

types:

Electricity used to run the pump.

For a modest sized pump, this might be 400 to 800 KWH a year if the pump

runs all the time.

Heat loss from the pipe.

Whenever the two pipes are hot, they will be losing heat. This heat

comes from the hot water tank, and the water heater must use more fuel to

provide the heat. The heat loss is significant even if the pipes are

insulated. During the winter, this heat may help to heat your house.

Or, it may not, depending on how the pipe is routed. This added heat

may be a benefit in the winter, but it will also add heat to your house in

the summer, which will just make it hotter, and may result in higher AC

bills.

How Much Energy is Wasted?

The systems vary in how much energy

is wasted. The ones that run a pump 24/7 obviously waste more heat and

electricity. The ones that work off a timer or thermostat would save some

of this waste, but not nearly all of it.

The "demand" systems would be much

more efficient, since they only circulate water when its actually needed.

I estimated the energy waste for

recirculation by measuring the amount of energy my gas water heater uses with

and without the recirculation loop enabled. With the recirculation system

on, the gas burner comes on every 1.25 hours for 5.1 minutes. With the

recirculation system off, the burner comes on every 5 hours for 5.1 minutes.

All of these measurements were taken over the night period when no hot water was

being used. If you go through the math on this (see below), it comes out

to 200 gallons of extra propane wasted per year to support the

recirculation system.

For the 8 years we have been in this

house, and using the current price of propane, this is $3,200 worth of wasted

propane. Not to mention the 21,000 lbs of CO2 emissions.

Note that in our case the

recirculation loop has no pump at all -- the water just thermosyphons through

the loop. The loop originally had a pump that ran 24/7, which I removed

when we moved in. Had I left the pump in, and running 24/7, the

electricity consumption would have been 745 KWH per year. For the 8 years

we have been here, this is nearly 6,000 KWH worth $600 at our electric rates.

In addition, 12,000 lbs of CO2 would have emitted.

Recommendations

If you are doing a new house, try and

avoid any need for recirculation systems at all. Try to locate the hot

water using fixtures as close to the hot water heater as possible. Using a

"Home Run" plumbing system

will also help greatly to minimize the wait for hot water and the waste of

water.

If you are going to use a

recirculation system, use an efficient one. The demand style systems

will waste far less energy than the other types of systems. The demand

systems may cost a bit more, and may be a little less convenient to use, but the

saving in energy and greenhouse gas emissions are well worth it. While

these systems still lose all the energy used to heat the water left in the

supply pipe after using hot water, they at least don't keep reheating the water

in the pipes constantly, and they don't constantly waste electricity to run the

circulation pump.

Even if you don't use a recirculation

system, or use the more efficient on demand system, you will still waste the energy that went into heating the water in the line out to the far

fixture every time you use hot water. This water just gets left in the

pipe and cools down to house or crawl space temperature. In our case, this

is about 2 gallons of water. Heating this 2 gallons of water costs

about (2 gal)(8.3 lb/gal)(120F - 50F)(1 BTU/lb-F) = 1170 BTU. If you do this 4 times a day, it

amounts to 1.7 million BTU/year, or 18 gallons of propane a year. The only

way to avoid this energy waste is to locate the hot water tank near the

fixtures, and use the Home Run system mentioned to minimize the water volume in

the pipes.

We are still trying to figure out the

best way to fix this problem at our house. We are considering the on

demand circulation system, or adding a separate tankless water heater to serve

the distant bathroom. Since this is our main use bathroom, we are leaning

toward adding the new tankless heater to serve this area.

| |

Update Feb, 2008

Tankless Water Heater

We decided to solve the problems of energy waste caused by the

recirculation system by installing a Takagi tankless water heater in the

crawl space under the far bedroom. This tankless supplies only the

far bathroom, which is our main area for using hot water. It

probably accounts for around 80% of our hot water use. It runs on

propane, and has an energy factor of 0.85, and no standby losses or

water recirculation losses.

This also works out well in that it allows a straight forward way to

connect the solar water heater that we are adding.

The installation was fairly time consuming in that it required

running a new gas line to that area, rearranging and adding some

plumbing, installing the through wall exhaust vent system, and adding a

new outlet in that area. This took the equivalent of two full days

of my amateur labor. Most installations would be much more

straight forward.

So far, we really like the tankless heater.

It supplies hot water quickly and endlessly and without waste of energy,

and its very quiet. It is amazingly compact.

The new Takagi tankless installed.

Update

April, 2009: We have added a

solar water

heating system to preheat the water coming to this tankless heater.

The solar water heater is actually

satisfying

nearly all of our hot water demand. Had I known that the solar

water heating system was going to do so well, I probably would have put

a simple electric tank heater in with lots of insulation. While I

don't like heating water with electricity due to the high CO2 emissions

from our electric grid (3X those for propane or NG), with the solar

heater providing nearly all our hot water, the electricity use would

have been small. |

Comments on this?

Gary...

| |

In an email comment, Ron points out

that I do not give credit to the recirculation systems for the water

they save.

This is a good point. Even the most energy inefficient

recirculation systems save some water on every hot water use. The

amount will vary with the length of your plumbing runs, but in our case,

its as much as 2 gallons for each use. In our case this

might add up to nearly 5000 gallons per year.

The impact of this extra water use would vary depending on where you

live and what the water situation is there. In some areas, the

impact of this extra water use may be small, but in others it could

certainly be significant.

I suppose this puts even more emphasis on designing systems from the

start that are efficient both in water use and in energy use. As

discussed above, this means placing the hot water source and hot water

use points to minimize water in the lines, and using minimum diameter

plumbing runs (e.g. the Home Run systems).

If you are stuck with long plumbing runs and long hot water waits,

then using the most efficient of the recirculation systems, or adding a

hot water source near the distant point of use are the options that save

both energy and water. |

Estimate Details

These are the details on how I

measured the energy wasted by the recirculation system on our house.

Our house uses the type of system in

which an extra pipe is added allow water to be circulated out the hot water

supply pipe, and then back to the tank using the extra pipe. The supply

pipe is 3/4 inch copper, and the extra return pipe is half inch copper.

The runs about 60 ft long. All of the lines are insulated. While the

system initially had a Grundfos UPS 15-42 circulation pump, I removed the pump,

so the water circulates only by thermosyphoning through the pipe. Before I

took the pump out, it used 85 watts 24/7, or about 745 KWH/year!

The tank temperature is set to about

120F. About half of the pipe run is through the ceiling of a

finished basement, and the rest is through a crawl space.

The hot water tank is a Rheem power

vent tank. Whenever the tank needs to run the burner to maintain

temperature, the burner turns on, and an electric blower turns on to exhaust

combustion products. The blower motor and the burner are on for the same

amount of time.

I used an Onset motor on/off logger

to log the time the blower was on (see plots below). I did the

logging at night so that there would be no hot water demands to confuse the

issue. Here is how the

logger was setup and

used ...

|

The results were:

With the recirculation

loop on: burner on time was 5.1 minutes every 1.25 hours.

This is 4.1 minutes/hour,

or (4.1/60 hr/hr)(24 hr/day)(365 day/yr) = 598 hr/year

With the recirculation

loop off: burner on time was 5.1 minutes every 5 hours.

This is 1.0 minutes/hour,

or (1.0/60 hr/hr)(24 hr/day)(365 day/yr) = 146 hr/year

The water heater burner

input rate is 40,000 BTU/hr.

|

|

So, the burner runs 452 hours

more per year with the circulation loop on (598 hr - 146 hr = 452 hr).

The increase in energy

consumption for recirculation is then:

(40,000 BTU/hr)(452 hrs) = 18.08

million BTU/yr

Propane has a heating content of

92,000 BTU/gallon, so, the 18 MBTU equates to 197 gallons of extra propane

per year.

In our area, this is $394 worth

of propane per year.

Over the 8 years we have been in

this house, this is $3150 worth of propane!

These are the logger plots

showing the burner on times over two nights -- the first plot has the

circulation loop on, and the 2nd has the circulation loop off. I have

done this on several nights with the same result.

Burner on times with the

recirculation loop in use. Approximately 5.1 minutes every 1.25 hours.

Burner on time with the

recirculation system turned off. Burner on time approximately 5.1

minutes every 5 hours.

Gary Jan 16, 2008