Search

The Renewable Energy site for Do-It-Yourselfers

Acrylic Sheet

Inside Storm Windows

|

On some of our windows, we are using a

single sheet of eighth inch thick clear Acrylic plastic sheet.

The sheet attaches to the window frame via spots of Velcro on the frame.

These are very easy to do, not too expensive, and probably add at least R1 of

thermal resistance. Payback is excellent -- see below.

In the summer, we will take the Acrylic

panels down and store them.

Be careful not to block a window that

is required as an emergency exit, and don't use these Acrylic windows where

there are big time heat sources nearby (e.g. wood stoves).

NEW

-- large window example...

|

|

Here are some pictures:

This is the Acrylic panel in the

process of being installed. I did a sloppy job on the Velcro. For

the next set I'll use the little round spots of Velcro, and get them in a

color that matches the windows frame. I'll also use panes that cover the

entire window, rather than the two panes I used on this one.

With Acrylic panel installed.

The slight fuzzy look is due to the insect screen on the window. The

Acrylic panels themselves are very clear -- you can't really see them at all.

Economics:

If you live in a 7000 heating deg-day

climate (mid to north US), and you have single glazed windows now, then for an

example 3ft by 4ft window, you might save:

Window area = (3ft)(4ft) = 12 sqft

R value for single glazed windows

= 1

R value with Acrylic pane added

= 2

Heat Loss single glazed = (7000

deg-days)(24hr/day)(12 sqft)/ (R1) = 2,016,000 BTU per season

Heat Loss with Acrylic pane =

(7000)(24)(12)/(R2) = 1,008,000 per season

Cost saving if you use propane in an

70% efficient furnace is:

Gallons saved =

(2,016,000-1,008,000BTU)/((90,000BTU/gal)(0.7efic)) = 16 gal/yr saving

Around here, that's worth about $32

per year.

The Acrylic costs about $2 per square

foot here, so this 12 sqft window would cost about $24 to do.

So, the payback for single glazed

windows is less than one heating season!!

For double glazed windows, the

saving is about $11 per year, so the payoff would be about 2 seasons.

Still a 50% return, inflation

protected, tax free investment -- try and get that on the stock market :-)

And, it may qualify for a tax credit

-- take a look here and see:

Rebates

My state (Montana) pays 100% of the

cost under the current tax credit for energy improvements program.

Larger

Window Example

This is an example of using an

Acrylic inside storm window just like the ones above, but on a larger window.

It also shows how it works well on

windows with an irregular shape.

Because the larger Acrylic sheets are

kind of large and floppy, this is a bit more work than the example above.

There are times when it would have been nice to have a 2nd pair of hands

available.

The two large panes with the trianglular tops have the added pane of clear

Acrylic installed in this picture.

This is the larger windows with the

inside Acrylic panels installed.

The Acrylic is so clear that you

really have to look twice to see that anything has been added.

These windows are about 58 inches

wide.

These inside storms will stay up year

round as they are on fixed (non-opening) windows.

I used fairly thin Acrylic sheet

(about 1/8th inch) that I special ordered from Home Depot. Don't remember

the exact price, but it was fairly inexpensive. The down side is that Home

Depot requires that you order more than on sheet -- I had to order 4 sheets, but

I have used nearly all of it.

The techniques for cutting etc are

the same as decribed for the smaller window above.

I made the long cut to width on the

table saw with a finish cut blade.

The angled cut across the top of the

window was made with an electric sabre saw as shown below. The Acrylic is

thin and a little bit brittle, so you do have to use some care in the cutting.

Use a fine tooth blade (like a metal cutting blade), and support the work on

both sides. Go fairly slow.

The most difficult part of doing the

larger windows is putting the larger pane of Acrylic in place. Its kind of

floppy, and takes a bit of patience to get it in position. A second

pair of hands might be a good deal. With a large pane like this, I think

that screws going through the Acrylic and into the window frame are better than

Velcro. I used 9 screws around the periphery to hold the pane in place.

They don't have to be very big screws, and be careful to make sure that you

don't get to close to the glass panes with the new screws.

Small screws hold the Acylic in place -- this is 1 or 9 screws.

This took about 2 hours to do both

windows.

Starting with double pane windows, in

our climate, and with propane fuel, the saving per year is about $46, with a 280

lb per year CO2 saving. Not bad for a couple hours work :)

The saving for a single glazed window

would be quite a bit better.

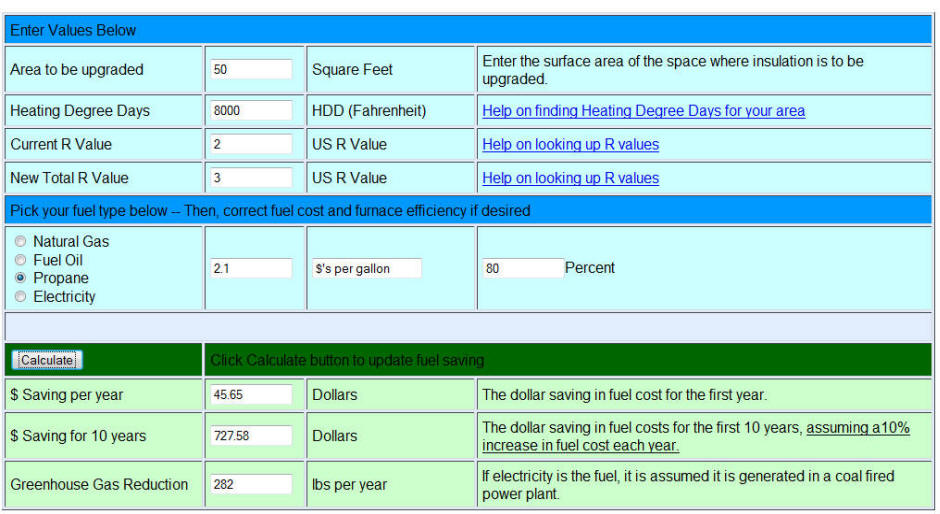

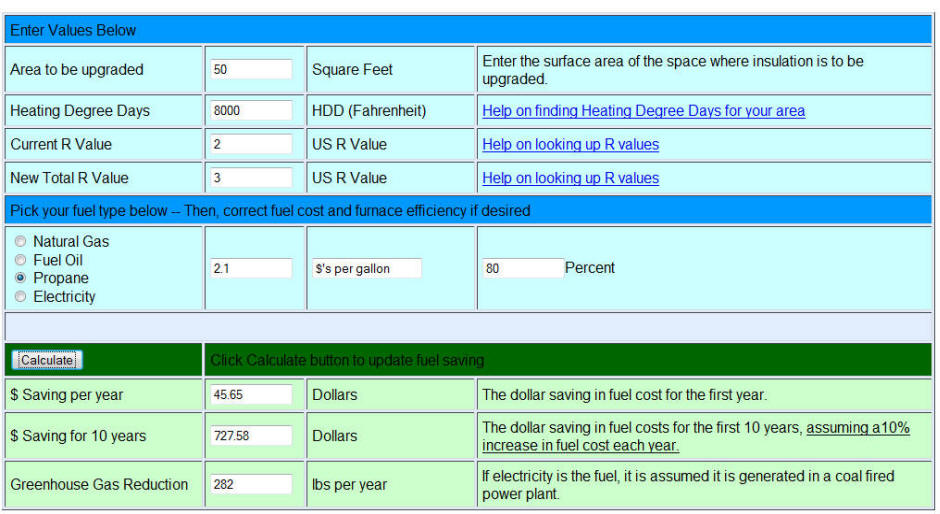

Here is the Insulation Upgrade

Calculator output:

If you want to run the calculator for

your own case,

its here...

Gary

12/5/05

Added large window December 11, 2009