Search

The Renewable Energy site for Do-It-Yourselfers

Report and Thoughts on Treated Lumber PV Array Mounts

|

Back in 2009 I built a ground mounted PV array for my house. The mounting system used treated 4 by 4 treated lumber for the array supports.

There was some concern expressed that the treated lumber would not have a good life. So, this is a report on how things are going so far with the treated lumber mounts, and some thoughts on treated lumber and design details.

|

|

How the Mounts are Doing So Far

The mounts are about 4 years old now, so not old enough to tell a whole lot, but here are some pictures of the mounts as they are today:

So, they look fine so far -- its hard to tell these pictures from the ones taken right after the build.

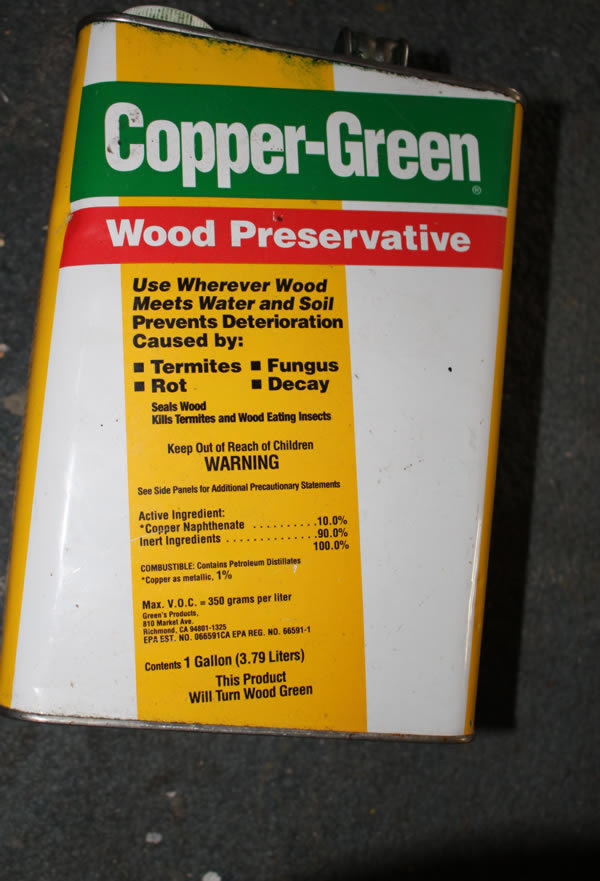

About every 2 years, I've been applying Copper Green, which is a Copper Naphthenate based fungus, rot, decay and termite treatment. I put on a liberal coat in the areas that are the most likely to be effected by decay, such as the timber ends, and the base of the vertical posts where it enters the concrete. I put the Copper Green in what was a small weed sprayer and give all these areas a good dowsing. Takes about 15 minutes to do this. Doing this every two years may be overkill, but it does not take long or cost much.

These are pictures of the treated posts on our fence that has been in for about 12 years without any treatment other than the original factory pressure treatment.

No visible decay.

Wood Treatments

There are a variety of wood treatments for decay, but the most common for wood that consumers can buy is the CAC (Copper Azole) type. This treatment uses copper as the ingredient to prevent decay instead of arsenic, which was used in the ACQ treatments and has been phased out for consumer wood.

Various grades of treatment are availably with the more treatment material going into the grades that are rated for ground contact and even more for wood rated for use in foundations.

You should pick treated lumber that is at least rated for ground contact. If you can get treated lumber that is rated for use in building foundations (FDN grade) that would be all the better. The tag on the treated lumber will say what its rated for.

Foundation grade treated lumber has been field tested in areas that are very hard on wood (e.g. southern Mississippi) for periods in excess of 30 years with no failures.

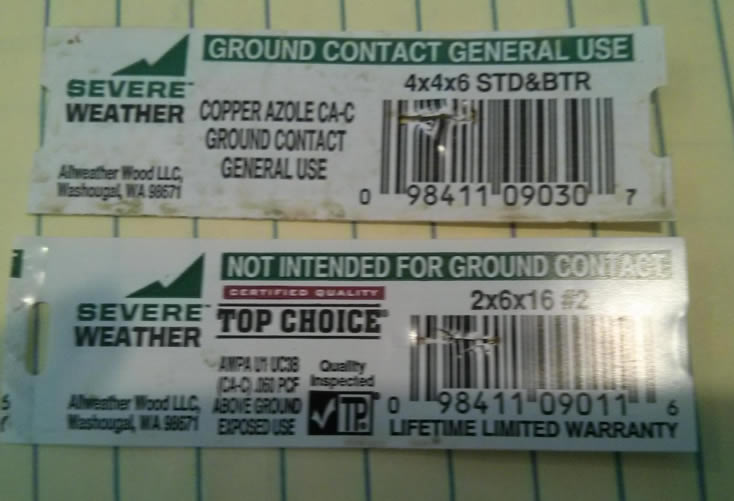

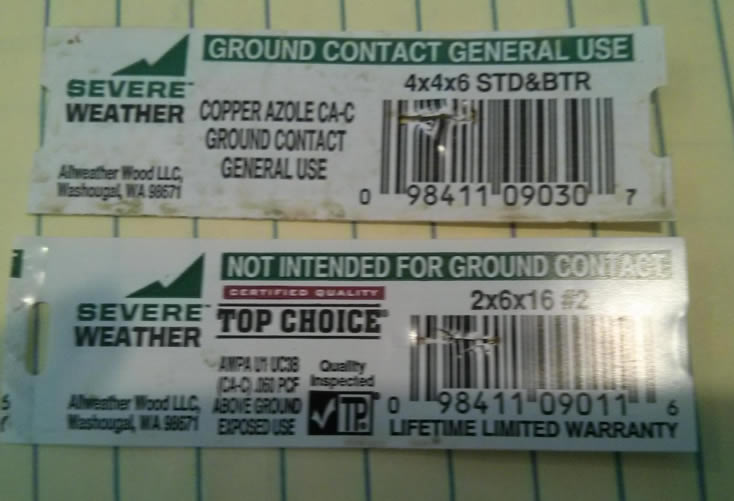

Labels from treated lumber at our local Lowes. There are other grades that are intended for wood foundation are treated more thoroughly.

Of course, you want to be careful to throughly treat any cut ends either by soaking or multiple liberal coats of something like Copper Green.

With the CAC treated lumber, it is also important to use fasteners and metal fittings that are rated for use with CAC as the CAC is more likely to cause metal corrosion.

Potential Design change

The part of my design that is probably the most susceptible to long term decay is the way in which the back 4 by 4 legs go into the concrete footings. It would be possible to use the type of anchor (picture below) in which a galvanized fitting goes into the concrete, and the 4 by 4 is attached to the galvanized fitting. This keeps the 4 by 4 out of contact with the concrete/dirt. Diagonal bracing would have to be added between the back posts to restore the shear strength of the mounts.

This kind of an attachment would also make it relatively easy to replace timber that was damaged by rot or whatever if need be.

Conclusions

I feel that the timber supports on my array will go the distance with some occasional re treatment as described above, but I do live in an area where wood decay is not typically a big problem.

So, if you live in an area where wood decay is a problem, then I would either make sure that the treated wood used is the foundation grade (FDN), or use one of these galvanized steel support schemes. Either of these approaches should give you a mount life longer than the PV module life.

Properly galvanized metal pipes should have a good life in most soils and in concrete, but contact with other metals can result in galvanic corrosion, and precautions should be taken to avoid this.

Just as an aside, we have experienced several high wind incidents with no damage. I've gone out to the array during high winds and the amount of movement caused by wind gusts is nearly imperceptible.

Gary

September 9, 2013.