Search

The Renewable Energy site for Do-It-Yourselfers

How the Riversong Modified

Larsen Truss Design Evolved

|

Robert Riversong describes below the how his version of the Larsen Truss evolved

through several home construction projects. He provides much useful

construction detail for the truss, and for other sustainable building and living

practices.

For a more detailed description of

the Larsen Truss design he uses now look here ...

Thanks again to Robert for providing

material on this very well thought out design.

|

|

Larsen Truss

Robert Riversong

John Larsen of Canada invented a

simple parallel-chord wooden truss as a method for superinsulating existing

houses. The idea was to strip off old siding and cut off existing roof

overhangs, nail trusses onto the walls and over the roof, creating a new

overhang. Then new sheathing, siding and roofing could be applied, and perhaps

new windows. Alternatively, the existing windows could be left in place

and extended exterior window boxes and sills created. This would turn an

old, drafty house into a superinsulated home without any disturbance to the

living space (unless windows were replaced).

The truss cavity could then be filled with blown

insulation. Additionally, a vapor barrier could be applied over the existing

wall sheathing before installation of trusses without fear of condensation as

long as 2/3 of the R-value of the envelope is outside of the barrier.

I learned about this wall system when I studied

energy-efficient building at Cornerstones School in Brunswick Maine in 1982.

The school was spun off from the nation’s first owner-builder school, Shelter

Institute, and founded by engineer Charlie Wing (author of From the Ground Up,

From the Walls In, and the recent Visual Handbook of Building and Remodeling).

The lead instructor was Dale McCormick (author of Against the Grain: A Carpentry

Manual for Women) and the one of the first women to become a union carpenter. I

also read about it in Don Booth’s seminal book Sun/Earth Buffering and

Superinsulation.

But, before I used the Larsen Truss approach, I

experimented with a variety of double stud wall systems, each of them

problematic for a variety of reasons. When I was asked to build a low-cost home

and pottery studio for a wonderful couple who had been saving for 14 years, I

decided to try the Larsen Truss.

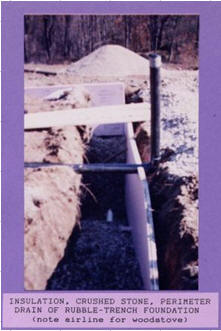

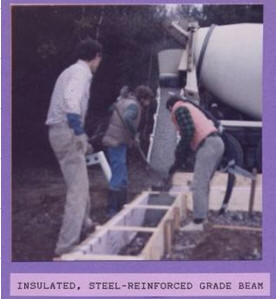

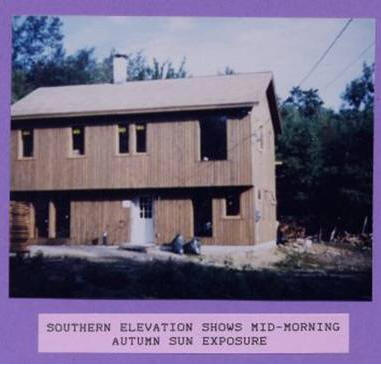

This

house was built on a foam-insulated reinforced concrete grade beam on a

rubble-trench foundation, with an insulated flagstone on sand bed first floor.

All the framing was green rough-sawn lumber custom milled to full dimension.

The load bearing walls were 2x6 for the first floor and 2x4 for the second, set

on PT plywood subsills on recycled tin printing plates for insect barrier.

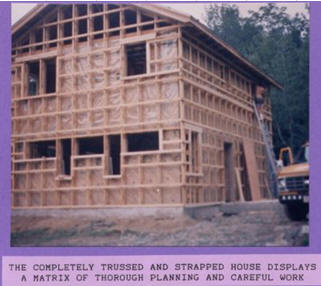

The exterior walls were sheathed with rough-sawn diagonal

boards and then wrapped with 8 mil stabilized Swedish Tenoarm vapor barrier,

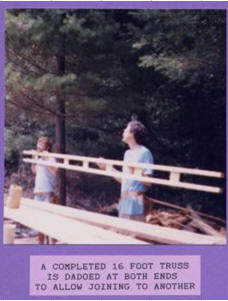

installed like housewrap with one taped seam. The trusses were fabricated by

ripping KD 2x4s, dadoing 3/8” slots 24” oc, and glue-nailing plywood gussets

into the slots. They were a standard 16’ in length with dadoes at each end for

splicing to another truss section.

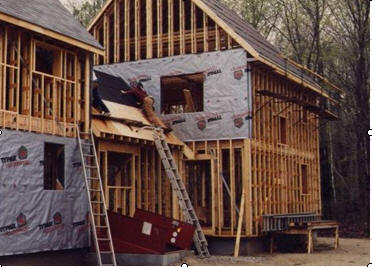

The prefabbed trusses were then nailed to rafter tails,

through the sheathing to 24” oc studs, and extended to sit on a bottom plate on

the plywood subsill. Because the owners wanted vertical siding, we nailed

horizontal 2x2s 24” oc and then wrapped Typar over the cross-hatched

exoskeleton. Pre-stained shiplap siding was installed over all.

The system was a bit labor-intensive, but there was only

one other paid carpenter and the homeowners comprised the rest of the crew.

|

The primary drawback of the system was that we were left

with two insulation cavities. I wanted to use blown cellulose, but to get in

into the truss cavity now that it was sided we had to use a holesaw to cut

through the inner sheathing and the vapor barrier. I used the Tenoseal adhesive

which came with the Tenoarm to seal the holes with plastic patches after the

insulation was installed. But, since I didn’t feel like renting the cellulose

blower again and making holes in the drywall, I decided to insulate the inner

wall cavities with unfaced fiberglass. Because this was my first attempt at

blowing cellulose and I had access only to a rental blower of questionable

quality, I was concerned about potential settling under the deep plywood window

boxes. So, since I had fiberglass on site, I stuffed an R-19 unfaced batt under

each window box so that it would be compressed by the dense-pack cellulose and

re-expand if there were to be any settling.

The house was certainly a success, operating as designed

to require only 4/5 of a chord of wood per year to heat. It used the small

Yotul woodstove as the exhaust system and relied on passive make-up air inlets,

some of them site-built to take in air under the south garrison overhang and

duct it both to the downstairs ceiling and through the upstairs floor. The

woodstove also had a subfloor combustion air inlet that terminated at a floor

register near the hearth. And a radon vent went from under the slab to above

the roof.

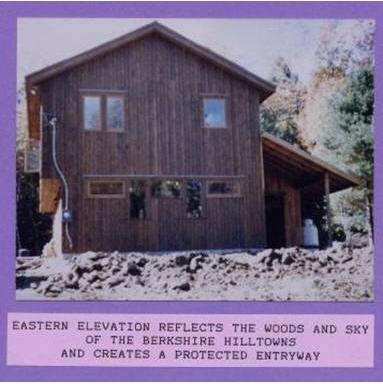

The 1400 square foot studio/house was completed in 1987

for $48,000 including site work, well and septic. It won a Citation of

Excellence from a national Energy & Resource-Efficient Design Competition

sponsored by the Northeast Sustainable Energy Association.

My next opportunity to use the Larsen Truss was in 1993,

when I volunteered to chair the design committee for a community-based

non-profit building project called Building Our Swords Into Plowshares, which

was the Gandhian “constructive project” of the 18-month long War Tax protest in

Colrain Massachusetts following the IRS seizure and auction of a home. With the

help of architect Bruce Coldham, I eliminated the problems of my first

experience by creating a “modified” Larsen Truss, using the load-bearing studs

as the inner chord of the truss. By installing metal T-bracing in the frame for

rack bracing, we eliminated the need for sheathing, used less lumber and created

a single insulation cavity to be filled with dense-pack cellulose. We also used

horizontal novelty drop siding so that additional nailers were unnecessary.

This proved to be a simpler, more resource-efficient, and

easier-to-insulate wall system. Instead of vapor barrier, we employed the

Air-Tight Drywall Approach (ADA), which involved caulking each framing layer to

the next at the perimeter with Tremco acoustical sealant, and applying the same

sealant to top and bottom plates as drywall went up. Polypans were also used

around electric boxes, whose wide flanges offered a caulking surface for the

drywall membrane. This was actually less work than installing a continuous

vapor barrier. To make the inspector happy, we used Glidden vapor retarder

primer (no longer available, but Sherwin Williams makes one).

The Plowshares duplex was completed with the help of 300

community volunteers, and eventually was transferred to Pioneer Valley Habitat

for Humanity along with an extra lot on which they built another single-family

home.

Frame is KD 2x4 and trusses are 2x4s ripped into 2x2s with

plywood gussets.

The next time I had an opportunity to design and build a superinsulated house

was for some dear friends of mine I had known at the Noonday Farm Catholic

Worker community in north central Massachusetts.

This would be a 1440 square foot, 3-bedroom home

overlooking an organic farm field. Initially, they had considered an earth-bermed

house with concrete walls tucked into a south-facing slope. But when they

realized they could have a highly energy-efficient passive solar home with views

of their farm field, good daylighting and ventilation, they were happy to shift

gears and scrap the plans drawn up for them by an engineer friend who had

designed America’s first Peace Pagoda for the Nipponzan Myohoji Buddhist order.

So we spent the winter designing and planning a modified

Larsen Truss home which was to include a solar-heated indoor planting bed, wood

heat and cookstove, provision for heating hot water with a coil in the cookstove,

and Massachusett’s first approved site-built composting toilet. It was also

built to the Energy Crafted Home program which offered incentives for

efficiency.

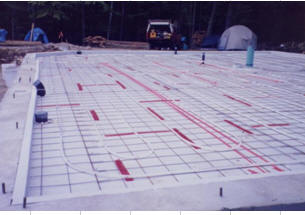

Because the homeowners wanted to store solar heat for

their planting bed in six 50-gallon black plastic barrels behind south-facing

glazing, I suggested that we install radiant tubing in the slab with a

circulator and aquastat so that, if there were enough temperature rise, excess

solar heat could be stored in the floor. As I suspected, however, there was too

little surface area to volume ratio in the barrels to get the water hot enough

for efficient heat exchange.

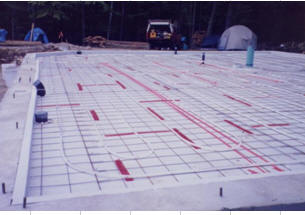

The slab was poured inside a shallow, frost-protected grade

beam and on top of radon mitigation piping. The frame was a hybrid stick and

timber frame, with exposed interior load-bearing timber bents using a simplified

pegged joinery system that I designed.

Radon piping |

Radiant Tubing & Wire Mesh on R-10 Foam |

Parging the exterior foam with surface-bonding cement over hardware cloth |

Trimming Timbers |

Superinsulated Compost Chambers |

The house was built entirely of

local rough-sawn hemlock, including subfloors and roof sheathing, and the siding and trim was planed local

hemlock prestained in a dipping bath.

The interior load-bearing 2x4 frame was braced with let-in

steel T-bracing, and the outer truss members were 2x3 with 1x4 gussets to tie

them to the structural studs.

The air-tight drywall system was used to make the envelope

impervious to infiltration and to avoid the need for a vapor barrier.

Northeast Entry

|

South Façade with Solar Shading |

Northwest Corner with Compost Cleanouts and Turbine Vents

on Roof |

Water Barrel Solar Storage

|

Finished Planting Bed |

Tiled Entry

|

Tiled Woodstove Surround & Hearth

with exposed timber ceiling |

Air-tight Pull-Down Attic Stairway |

With Superinsulated Hatch Above |

Indoor Two-Holer with Intake Vents, Exhaust Chases, & Fly

Catcher Jars |

|

The house cost a little more than

$100,000 (about $75/sf)

to build in 1998, and was designed to require 4/5 of a chord of firewood per

year for heat, in addition to passive solar gain. Indoor ventilation is

provided by passive fresh-air inlets, with bath and kitchen fans as well as

woodstove and wood cookstove serving as exhaust fans. The woodstove has a

nearby combustion air inlet register in the base of the chimney.

The compost toilet has been supplying clean loam for ten

years.

March 7, 2008