Search

The Renewable Energy site for Do-It-Yourselfers

Large Thermal

Storage Tank with Immersed Tank Heat Exchanger

|

This is a simple and elegant

thermal storage tank and heat exchanger installation from Alan Rushforth

of Rushforth

Solar LLC.

Thanks very much to Alan for

providing this material!

The tank provides thermal storage for

a large solar domestic water heating system in a 22 unit apartment building.

|

|

The 2000 gallon storage tank is 7 ft

high and 8 ft - 3 inches in diameter. It is made from a roll of 0.058 inch

thick sheet aluminum. The tank is just sheet metal wrapped into a cylinder

with the ends overlapped and fastened together. This is an efficient

design for a water tank, in that the water pressure loads are taken by simple

tension in the cylinder wall -- there are no bending loads in the tank wall.

The tank is insulated with 2 layers

of 1.5 inch rigid foam

board insulation on the inside and bottom of the cylinder. The insulation

is polyisocyanurate with aluminum foil face sheets. The tank is then lined with sheet EPDM. The EPDM liner is a single piece that

is just tucked and folded to fit the shape of the cylinder.

This is a drain back system, and the

tank is vented to the atmosphere (not pressurized). When there is

enough sun, water is pumped from the tank and up to solar collectors mounted on

the roof. The heated water is returned to the storage tank. Note the

two pumps that are connected in series to pump the water from the basement all

the way up to the roof.

The water to be heated for the people

in the apartment flows through the two stainless steel tanks that are immersed

in the large tank. Heat is transferred from the storage tank water to the

potable water by conduction through the stainless steel tank walls. This

preheats the water before it goes to the conventional water heater for the

apartment. The stainless tanks are about 50 gallons each.

During periods of low demand, the water in the immersed tank heats up to the

full temperature of the storage tank water, and provides some storage of

preheated water to satisfy high demands. If the preheated water is not hot

enough for final use, the conventional water heater will take it up to

temperature.

Note that all plumbing connections

are made above the waterline in the storage tank, so there are no penetrations

of the liner below the waterline that might leak later. The "U"

shaped loop that goes down the side of the tank to the two pumps, and then back

up to the output line to the collectors insures that the pumps retain their

prime.

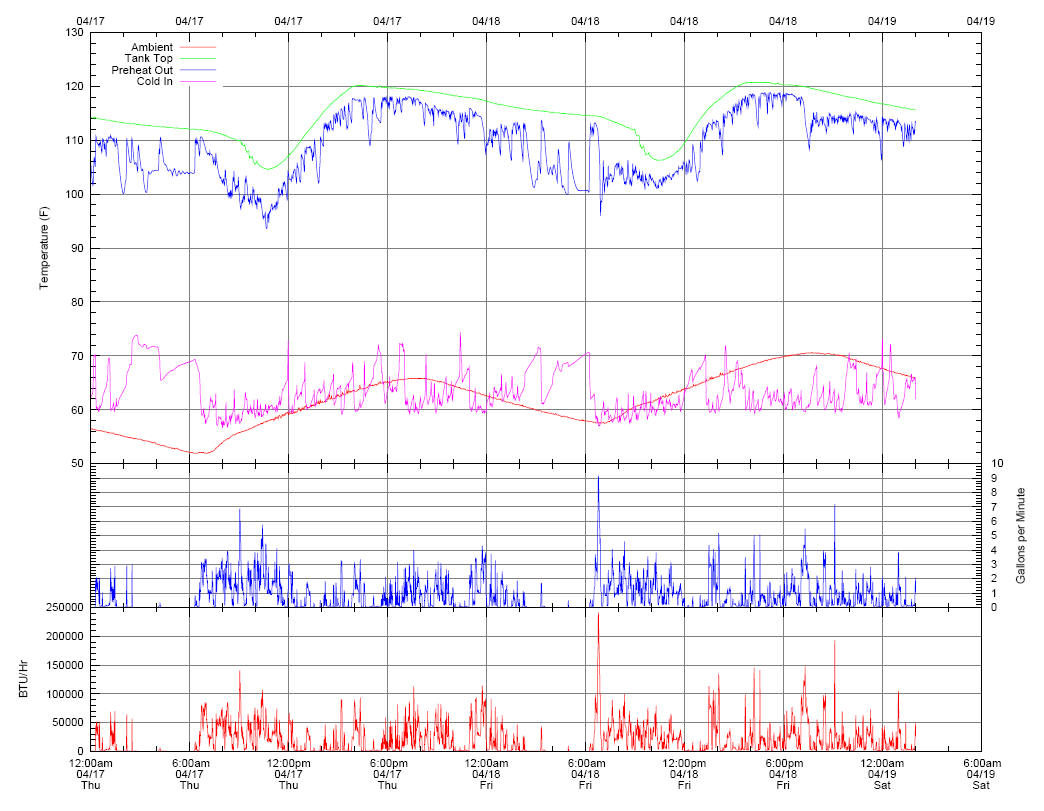

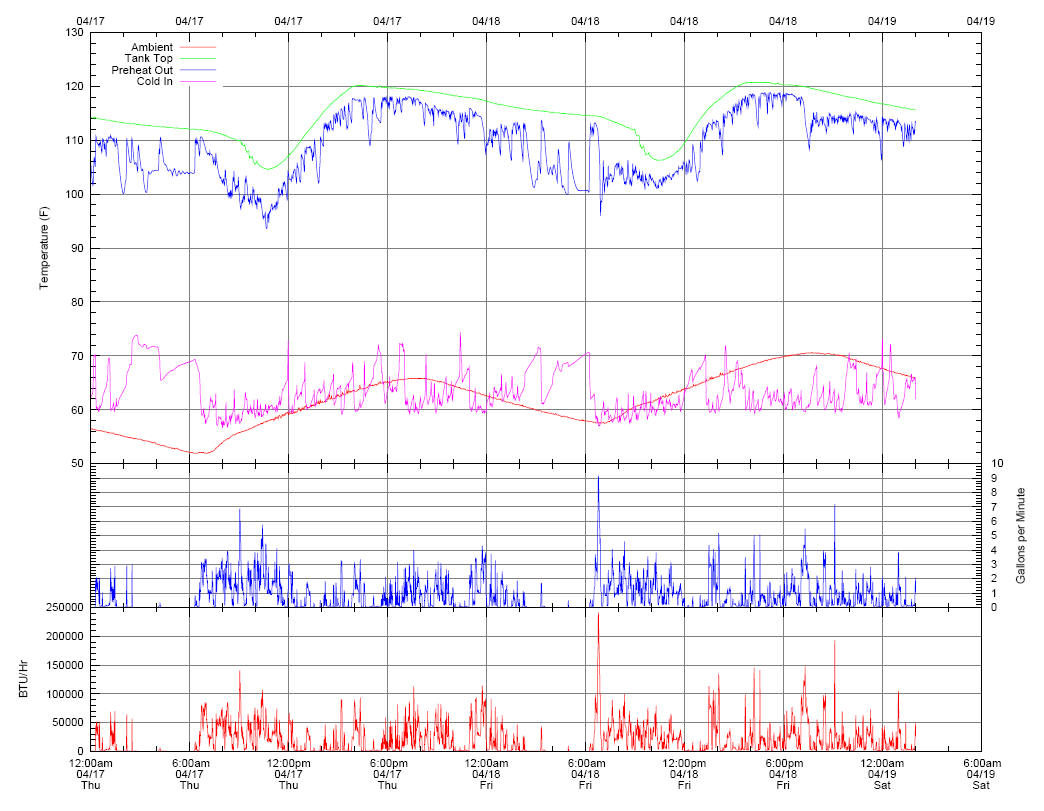

The immersed tanks appear to be doing

a good job -- see the performance plot below.

So, this shows two nice ideas:

-

The simple metal hoop cylindrical

tank lined with EPDM. This is an efficient and relatively easy to make

tank. It provides a lot of storage at a reasonable price.

-

The use of a small tank(s)

immersed in a large tank to act as a simple heat exchanger.

You probably don't need an

installation this large for your house, but it can be scaled down appropriately

to your water or space heating needs.

Another variation on this theme would

be to use a large coil of PEX or even HDPE pipe in place of the immersed tank

for the heat exchanger. An immersed 300 ft coil of 1 inch pipe would hold

12 gallons of water, and even when the 12 gallons was exhausted, it would have

enough surface area to act as a pretty good heat exchanger.

All of these immersed tanks or pipe

coil schemes are single wall heat exchangers, so the fluid on the outside of the

exchanger tank must be non-toxic, and you should check with your local code

folks to make sure this arrangement is legal in your area.

From Alan:

"I am pretty pleased with the

performance of the immersed tanks. Two of them (100 gallons total) works

pretty well. Three would been a bit better. After that - diminishing

returns. I am still thinking about using galvanized tanks for that - maybe

fed by pex/al/pex to minimize galvanic action."

The Alan made 2000 gallon thermal storage tank.

The two stainless steel heat

exchanger tanks mounted inside the thermal storage tank.

Performance:

Note that even with a 22 unit

building, the "preheat out" temperature never falls far below the "Tank Top"

temperature.

Alan Rushforth

Rushforth Solar LLC

www.RushforthSolar.com

AR@RushforthSolar.com

Bryn Mawr, PA

Gary April 25, 2008