Search

The Renewable Energy site for Do-It-Yourselfers

Solar Shed -- The

House Heating System

|

The 240 sqft of solar collectors

mounted on the new garden shed heat the water in the thermal storage tank also

located in the garden shed. To transfer heat to the house, hot water is

pumped from the storage tank via buried pipes to the house. The hot water

coming into the house is distributed to the new radiant floor to heat the house.

The old gas furnace forced air system

is retained for now to cover times when there is not enough solar heat.

|

|

Retrofit of Radiant Floor

These pictures show the installation

of the new radiant floor. The existing finished floor was removed to get

down to the subfloor. 3/4 inch plywood spacers were installed on the

subfloor with slots every 9 inches to hold the PEX heating tubes. Sheet

aluminum plates are used to spread the heat from the PEX tubes. A floating

finished floor of wood laminate was installed over this.

The radiant floor is an efficient way

to distribute solar collected heat because it can use relatively cool hot water.

Water temperatures as low as 90F will still provide significant floor heating.

Other water heating devices such as radiators require much hotter water to

provide heating. Being able to use cooler water allows the solar

collectors to operate more efficiently.

The new 3/4 inch OSB spacers being screwed down to the existing subfloor.

The PEX tubing will run in the gaps between the spacers.

This process raises the level of the

finished floor by about 3/4 inch, and may require a little trimming of the

bottoms of some doors.

This shows the aluminum heat spreader plates and the PEX tubing installed in the

grooves between spacers. The PEX tubing is PEX-AL-PEX -- this is PEX

tubing with a middle layer of aluminum. I used PEX-AL-PEX because it has a

lower coefficient of expansion than PEX, and because it is easier to work with

than PEX. It also conducts heat slightly better than PEX. A

bead of silicone caulk is placed in the aluminum heat spreader groove before the

PEX-AL-PEX is pushed into the groove -- this is to improve the thermal

connection between the PEX and the heat spreader.

The PEX-AL-PEX is half inch ID. The half inch seems to work pretty well.

It does not raise the floor too much. Most of my loops are from a bit over

200 ft up to about 250 ft. This seems to be working out OK -- with a flow

rate around 0.6 gpm, the temperature drop from the start of loop to the end of

loop with 100F water is about 10F, and the pressure drops over these size loops

can be handled with modest sized circulation pumps.

This home made press that was used to

form the groove in the heat spreader plates. The heat spreader plates are

made aluminum soffit panels sold by the local lumber yard. This was the

cheapest form of aluminum I could find. The thickness is 0.019 inch.

The panels come about 16 inches wide by 12 ft long. I cut these into

panels about 8 inches wide by 2 ft long on a table saw, and then formed the

groove with this press. The soffit panels already had shallow grooves, so

the press just expands that groove.

Click pictures to enlarge

The press pushes the steel rod into

the channel shaped jig formed by the two bottom pieces of plywood (see upper

pictures)

The rod is pressed down into the

groove by applying your body weight to the long handles.

The pivot axis for the handles is the

smaller steel rod that is visible coming out of the white block of plywood --

the mechanical advantage of the long handles allows you to apply quite a bit of

force.

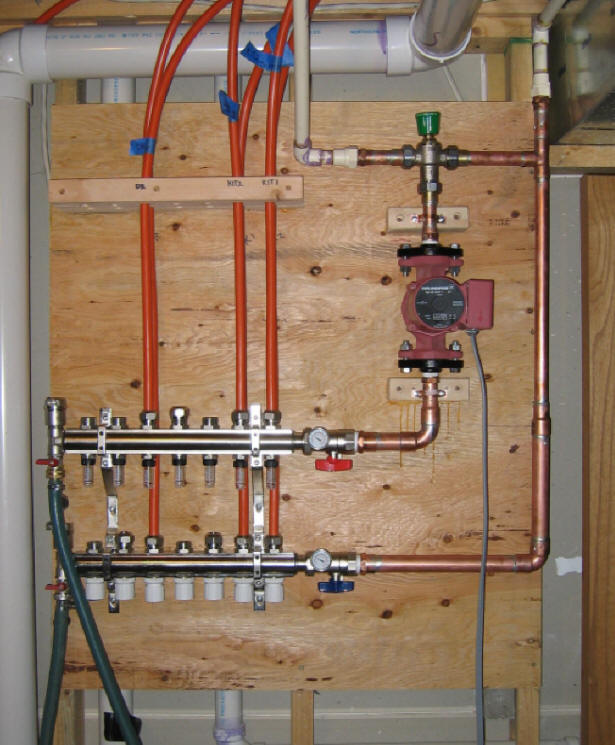

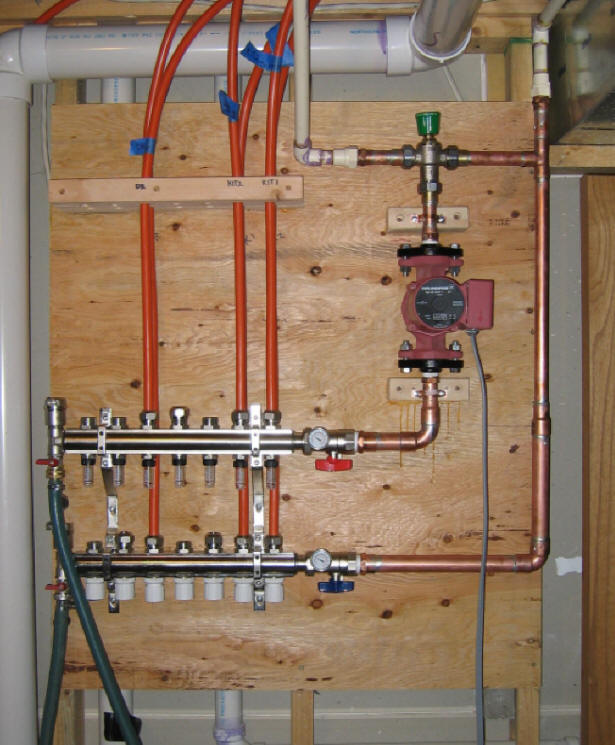

Radiant Distribution Plumbing

All of my floor loops start and end

at these manifolds in the utility room.

Radiant heating manifold. The

floor loops start at the upper (supply) manifold, and come back to the lower

(return) manifold. The manifolds were bought as a package that included

the manifolds, flow gages and shutoff valves for each loop, air eliminators

(on the left end of each manifold), temperature gages for each manifold, purge and

drain fittings, and shutoff valves for each manifold.

This manifold package was a bit pricy ($270),

but I have to say having the flow indicators, temperature gages, and shutoff

valves is a big convenience in determining what is going on, and in making

adjustments.

The supply pipe from the thermal

storage tank is the left of the two white 3/4 inch CPVC pipes coming down from

the ceiling.

The return to the storage tank is the

3/4 CPVC pipe to the right.

The return pipe connects directly to

the return manifold.

The supply pipe goes through the

thermal mixing valve (green top), through the Grundfos circulation pump, and

then to the supply manifold.

The thermal mixing valve mixes cool

water from the return line with the hot water from the storage tank to get the

temperature down to what you want to circulate through the floors.

The garden hoses connected to the

left side of the two manifolds were used to purge the system of air, and to fill

all the system lines with water, so that the circulation pump would work.

I was expecting this step to be difficult, given the very long underground line

between the storage tank and house, but it worked the first time.

This is really all there is to the

plumbing -- pretty simple.

Three more floor loops are to be

added soon to serve other parts of the main floor of the house.

Note: The

circulation pump was one that came with the house to circulate water in a loop

to reduce the wait for hot water in the bathrooms. When we bought the

house, it was running 24/7. At 85 watts to run the pump, this works out

to 750 KWH a year!, and $75 a year and 3/4 's of a TON of greenhouse gas.

I removed it from that job, and put it to work on the radiant floor -- I will

eventually replace it with a bronze pump with slightly larger capacity.

Gary 1/15/07