Search

The Renewable Energy site for Do-It-Yourselfers

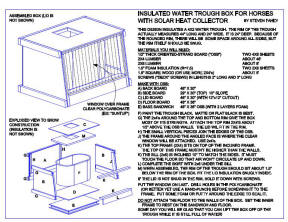

Heated Water Trough

for Livestock -- Using the Sun

Here's an interesting project that I took on this month. With winter coming, and

water troughs needing heat to stay thawed, I've put up with exposed steel

troughs long enough. Why these things don't just come from the manufacturer with

insulation wraps is a mystery to me. Three years ago, I built an insulated box

for a water trough, and it is still effective. Now that we have more horses, we

need more water troughs. Into the old water trough, I never built into it

provisions for putting in insulation. I decided that the second cover would be

better and have insulation.

To insulate mine, I had plenty of particle-board and 2x4's lying around, so

building a box to cover the trough was easy. I built this carefully, however, to

ensure room for the insulation and not much wasted space around the trough

walls.

To capture some heat from the sun, I found a great idea from Build-It-Solar, and

added a solar collector to one side. In that design, the water was held in by

walls of plywood, lined with plastic pool-wrap. It is very efficient from the

point of view of insulation, but it wouldn't survive the rigors of Alberta's

winters. I needed a different way to build this water trough. Ruggedness is

essential, because horses are like little bulldozers with teeth. Leaving a solar

collector within reach of their hooves invites disaster. And if it isn't

possible to throw in a floating water heater on seriously cold days, then

there's no point in doing this project. A solar collector will not melt water

when it's -30 overnight! Using a metal trough to hold the water was essential.

Here is the steel tank, a pretty typical 4' foot long oval trough.

For the solar collector to heat the water, the sunlight must be absorbed

efficiently. I painted the water trough black. It turned out that the black

paint was glossy, but I had a bit of matte left in a spray can, so I lightly

sprayed that on the side that would be in the sun. Sun entering the clear panel

hits the black metal water tank and passively warms the water. At the time, I

had no idea how strong the effect would be. Now that it's complete, I can feel

the effect when putting my hand under the lid.

So far, I used only left-over materials from other projects (building a new

barn, tearing down an old one, etc.). When it came to covering the solar

collector, I had some translucent panel materials, which also happened to fit

perfectly. Looking at them realistically, though, I realized that the fiberglass

panels would not let much light through directly to the trough. A lot of energy

would be absorbed into the fiberglass sheets themselves, defeating the purpose.

I went to the hardware store and picked up a clear corrugated polycarbonate

sheet (called "Suntuf"). It was easy to work with, and is very transparent.

I packed foam insulation into the walls, including making an insulated base with

a sandwich of plywood and foam insulation. The insulation in the walls is R=7.5,

and the double thickness in the bottom would be about R=15. Insulation on top of

the trough does two things. First, obviously, insulates the water from radiating

heat from the top surface. Second, the top sheet of insulation blocks air

circulation between the sun collector area and the air above the water. Why does

this matter?

Because you have to cut a hole in the

lid! The horses are getting thirsty! With a hole cut out, the air above the

water will almost always be cold. Wind makes that air circulate in and out of

the hole. If the air circulation also cools the air in the solar collector, then

the solar effect is diminished. There must be a seal between the two chambers.

Here it finally is, facing south (it

was sunset when I took the picture, so no more sunshine into the collector). The

cut-out in the top is 12"x12"; just enough for the horses to poke their noses

through. They took only a few days to get used to it. Some deliberate splashing

of water on their noses was all it took to make them understand that the water

was inside. Pieces of metal trim around the edges of plywood prevent chewing

(did I say they are like bulldozers with teeth? I meant beavers!)

Steven will answer email questions

at: sparweb AT hotmail DOT com (replace AT with @ and DOT with

a period).

Update: December 23, 2008

We've had two weeks deep cold without

a break. Daytime temperatures have not gone above -10C, and most overnights have

been -30C or worse. Winds come and go, and only 1/2 of the days have been sunny.

The insulated water trough is doing very well. It requires 1/2 of the

electricity to keep it thawed compared to an open trough. The floating electric

heater is controlled by an appliance timer, so it only turns on for 3 hours at a

time, 2 times a day. This is enough to keep it thawed even on the coldest days.

Several hours after the heater has shut off, a thin (1/4") layer of ice is the

most I've seen built up, and the heating cycle thaws that before the 3 hours are

up. The other steel trough that I have is identical, but it is only covered with

an uninsulated plywood box. This tank is in trouble at -30C, and requires

frequent ice-bashing. The electric heater in this trough uses almost twice as

much electricity, and it still doesn't keep up. I'm glad now that I insulated

the new water trough, and maybe before winter's through I'll have the old trough

insulated, too.

Steven Fahey in SW Alberta

Update:

April 15, 2009

This is the latest on Steven's solar

horse watering tank -- some very helpful information and results -- thanks

Steven!

Here are some pictures. The trough box shows hardly any wear-and-tear.

The Solar Tank after a full winter --

click on images for full size

| |

|

|

|

Now that winter is over, it was time to decide if I would take it apart or just

leave it. I took them apart the other day and here are some conclusions:

The electric heat hasn't been necessary for a few weeks, with temperatures

hovering just above freezing overnight. As you may recall, the other water

trough was covered but not insulated, and in the mornings where the temperature

had dipped below zero we would find ice, but not on the insulated one. The

uninsulated trough needed an hour or two of "on" time overnight to stay clear of

ice, when the insulated trough didn't need any.

I took the top off the insulated box and I saw no damage, no rot (rotting is

impossible in winter, of course), nothing split or moved by ice. The window was

intact, too. Facing the fence, it was never exposed to much risk of damage. In

the picture you can see that the sun angle is now so high that there is very

little light collected. The solar collector has an angle of 10 degrees, which is

only ideal for December and January.

On some winter mornings I discovered that condensation had frozen on the inside

of the window. The ice could be broken by tapping the window (Suntuf is

flexible) but if I wasn't there to do so, the ice inhibited the collection of

energy until it melted away.

Once the warm weather had come, the water in the trough rapidly turned green

with algae. The un-insulated trough did not have algae coloring in the water.

The insulated box makes for a much cozier environment! I cleaned both out,

finding only a little bit of algae on the walls of the tank in the un-insulated

box, but the algae had grown throughout the other tank. The insulation must be

removed when winter is over!

| |

|

|

Both troughs have had their respective boxes removed, and the covers have been

set aside. I think that next winter's water trough system will, of course,

re-use the solar trough, and the other trough will also be given a new cover.

That cover will have no solar heating window. The trough's location and

orientation precludes much direct sunlight for most of the day. In addition, I

have plans to create an adjustable temperature monitor using a PICAxe controller

to improve on the simple "on/off" timer system.

During this winter there was never more than 1/8" of ice to punch through on the

insulated trough - and then only on very cold mornings (-30C), after the timers

had kept the electric heat off for 4+ hours. The un-insulated box could develop

twice as much ice in the same conditions. No frozen-in water heaters, no broken

cables. Tripping of the GFI early in December turned out to be caused by a

defective heater. Returned to store and substituted a different model that

didn't trip the GFI. On two occasions, errors in programming the timers caused

two 1500W heaters to come on in the same circuit, causing the breaker to trip.

One of those instances was due to setting daylight savings time on one, and not

on the other. Duh!

Years before, keeping two troughs of water meant regularly bashing through

nearly solid ice, despite the heaters on 100%. Several times, repeated trips

back and forth to the house with buckets of hot water to thaw things out were

needed. There were also the frozen-in electric heaters and the broken electrical

cables immersed in water. All things of the past! Good thing I have all these

circuits GFI protected.

My total electricity consumption this winter between 1 December and 28 February

is roughly 10% less than it was last year. Considering my house's base load is

half of the total energy I used, and unaffected by this experiment, then the

"outside" power consumption was reduced by about 20%. A saving of about 200 kWh,

or 67 hours less time using two 1500W electric heaters. Just rough numbers,

here, but in the ballpark. By insulating the other trough, an additional saving

can be made next winter. If I can create a working temperature control, I can

improve those saving even more. Beyond that, I may be getting into diminishing

returns.

At 10 cents/kWh, my savings is about 20$, which pays for one of the timers. Next

year's savings will pay for the other one. Not a long pay-back time, even if you

were to take into account the wood and insulation materials, which stretches it

out to 5 years.

A couple more observations that

Steven passed along:

The ground under the tanks was

still frozen, so when removing the covers and troughs, I couldn't actually

move the insulated panels under the troughs until a week later. If the

ground can stay frozen for a week when temps rise from freezing to 20C, then

the opposite can be true, and the ground under the trough retains some heat

for a week when the temperature drops from 0 to -20C.

I foolishly forgot to plug the hole for the electrical cord, which went

through the solar chamber. This is probably what caused the condensation

inside the window.

The horses basically didn't take up any habit of chewing on the edges of the

box, because I put metal angles on all the edges and corners before putting

it in the paddock. Some horses chew, some don't. In my experience, horses

that don't chew wood will start if they ever see another one do it!

Update May

13, 2009 -- Summer Uses

Steve has found a great use for the

tank enclosure in the summer:

Hoping for actual tomatoes in July....

The lid stays off during the day, goes back on at night. We're still

getting frost some nights.

December 20, 2008, December 24, 2008,

April 20, 2009