Search

The Renewable Energy site for Do-It-Yourselfers

A Solar Water

Collector Made From CPVC

|

This was a quick prototype and test

of a solar flat panel collector using water as the heat transfer fluid.

The collector was constructed from CPVC plastic pipe. Radiant floor heat

transfer plates were used to absorb the solar energy and transfer it to the CPVC

pipe (see pictures). The collector is a small (5 sqft) size just to test

the concept. It is glazed with a single layer of PVC glazing from SunTuf

(see note below on this).

As an alternative to using the

(somewhat expensive) extruded alum fins, here are some homemade jigs to make

your own from sheet alum. Jigs. |

|

Construction:

The good news on this collector is

that it is dead easy to construct. It probably took less than an hour to

put the whole thing together.

-

Cut CPVC tubes to length (the

ratcheting scissors cutters they sell for this make this 5 seconds a cut)

-

Solvent weld the serpentine pipe

string together (fast and easy)

-

Put a bead of sealant in the

radiant floor heat spreader (to improve the thermal bond)

-

Tap the CPVC pipes into the radiant

floor heat spreaders

-

Paint the alum heat spreaders black

-

Build the box for the collector and

insulate the inside with Polyisocyanate type insulation.

-

Attach the glazing.

It could not be simpler.

Price:

The CPVC pipe and fittings are cheap.

The radiant floor heat spreaders that I used were fairly expensive, but there

may be cheaper ones out there, or it may be possible to fabricate them from

sheet aluminum.

Performance:

The performance graph and comments on

the performance are provided below.

Life:

The life of the collector is somewhat

doubtful. The temperatures in the stagnated collector are at or perhaps a

bit beyond the upper range of CPVC's rated capability. The fact that the

collector loop need not be operated at a high pressure probably helps.

Mounting the collector on a vertical wall where it would get less radiation

during the hotter summer period would also help. Covering the collector

with shade cloth in the summer would also help (this is actually recommended by

some commercial flat plat collector makers who make copper and glass

collectors).

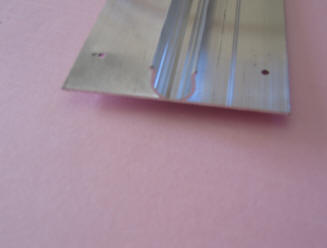

Assembling the serpentine CPVC pipe

run. The alum extrusion radiant floor heat spreader.

Tapping the CPVC into spreader

grooves. The finished collector.

The performance test setup.

Tilt was set to give normal incidence around solar noon.

Performance on a sunny day.

The temperatures plotted are:

Water inlet temperature (blue)

Water outlet temperature (red)

Collector air temperature near the

top (black) -- located in shaded spot at top of collector box.

Ambient temperature (green) -- badly

located.

Note that the ambient temperature

sensor was badly located and are invalid. The actual ambient temp was 62 F

at 11:20 am, rising to 77 F at 2:53pm.

This plot shows the performance for

the CPVC collector on a sunny day. There were intermittent thin high

clouds for part of the afternoon.

The collector was heating about 4.5

gallons of water from an uninsulated bucket. The flow rate at which water

was pumped through the collector was 0.5 gpm.

I also mounted thermocouples on the

radiant heat spreader fin with the following typical results:

T fin at outer edge

151 F

T fin near CPVC pipe

147 F

T of outer wall of CPVC pipe

103 F

T fluid

100 F

There is a big

temperature drop between the fin and the fluid (i.e. a high thermal resistance).

Most of this temperature drop appears to be taking place between the fin and the

CPVC pipe. Apparently there is not a good thermal bond between the CPVC

and the radiant heat spreader. This is in spite of the fact that the alum

heat spreaders are a very snug fit on the CPVC and there is silicone in the

groove.

I estimated the efficiency of the

collector by calculating the energy out from the flow rate and the inlet and

outlet temperature, and the energy in from the midday solar radiation at my

latitude and tilt. This came out to 60% -- I was surprised that it

was this good. And, 5 sqft of collector managed to heat about 4.5 gallons

in an uninsulated bucket to about 125F -- not so bad -- I am sure it would have

achieved a significantly higher temperature if the water storage bucket had been

insulated (you can see from the performance graph that the collector continues

to add heat to the bucket through the whole afternoon, the bucket is just losing

more heat than it is gaining due to no insulation).

If the thermal bond between the pipe

and fin were good, the fin temperature would drop down closer to the fluid

temperature. The fins would not run so hot, and would not lose so much

heat out the glazing. The efficiency and heat output would improve.

If you assume that for a good thermal bond that the temperature of the fins

would drop by 40F, and that the glazing is R1, then the gain in efficiency comes

out about +13% for a well bonded fin and tube. So, it appears that you do

take a pretty good hit for this construction.

Note on PVC glazing: I would

normally have use Polycarbonate glazing, but I had the PVC on hand and used it.

By the end of the test, there was an about 4 sqinch area near the top of the

glazing that had been permanently deformed by the heat. I would not

recommend using PVC in this application. Polycarbonate glazing

is good to about 270F, and should work OK.

Note also that I used the "pink" foam

board insulation because it was on hand. Polyioscyanate insulation should

be used because of its higher temperature capability.

Overall, I guess you have to weight

the time and cost savings against the poorer performance and shorter life.

I can't rule out the possibility that the life might be a lot shorter.

Gary

9/8/05

Some Additional Notes On CPVC vs

PEX:

It was pointed out to me by Burt M.

that PEX has a greater thermal conductivity coefficient than does CPVC. He

suggested that 1) most of the temperature drop may be in the CPVC wall (rather

than the thermal bond between the fin and CPVC), and 2) that PEX might work

better due to its higher thermal conductivity.

I am inclined to think that Burt is

correct on both points -- here are some tentative calcs to support this:

I had a go at calculating the theoretical temperature drop across the

CPVC tube wall using the the thermal conductance values you provided

above. If I did the math right (see below), then it takes a delta T

of about 26F to transfer the incoming heat from the fin (and sun)

through the wall of the tube. So, this says that about 65% (26F/40F) of

the

thermal resistance seems to be in the CPVC wall.

The PEX tubing I have has the same OD and ID as the CPVC, so the PEX

might be 2.1/0.9 = 2.3 times better, or about 11F to transfer the heat

through the PEX wall.

This says that PEX would do somewhat better than CPVC.

The wall heat transfer calc:

About (290 BTU/sqft-hr)(0.6 efficiency) = 174 BTU/sqft-hr gets to

each sqft of fin and is transferred into the fluid in the tubing.

Each sqft of fin (4 inch wide) is served by 3 ft of pipe.

CPVC half inch pipe: r2 = 0.3875 inch, r1 = 0.3125 inch

Ucpvc = 0.9 BTU-in/ft2-hr-F = 0.075 BTU-ft/ft2-hr-F

The transfer through the CPVC wall is:

q = UA(Touter - Tinner)

UA = (2*Pi*L*K)/ln(r2/r1)

UA = (2)(3.14)(3ft)(0.075 BTU-ft/ft2-hr-F)/(ln(0.3875/0.3125)

= 6.6 BTU/ ft2-hr-F

(Touter-Tinner) = q/UA = (174 BTU/sqft-hr)/(6.6 BTU-ft/ft2-hr-F)

= 26F

Since the PEX has about twice the thermal conductivity of CPVC, and the OD

and ID are the same, the temperature drop across the PEX wall would be less than

half as great.

Source for thermal conductivities:

CPVC at

http://www.boedeker.com/pvc_p.htm. (and many other plastics --

a good ref)

This gives a thermal conductance of 0.9 BTU-in/ft2-hr-F.

Compare this with aluminum at about 1500, or copper at 2700!

PEX tubing thermal conductivity: 2.43 BTU in/hr-ft^2-F per DIN52612

http://www.viega-na.com/downloads/1201700887SP-11108-1106%20Pextron%20Tubing.pdf

Apparently PEX has significantly higher conductivity than CPVC.

PEX-AL-PEX is even better.

Gary

09/11/05, April 4, 2008