Search

The Renewable Energy site for Do-It-Yourselfers

Solar Pond Domestic Hot Water Heater

-- Prototype 3

|

This is an update on the simple solar

water heating system that Nick Pine and I have been working on.

This is the third prototype. It

is showing some promise, but still has at least one unresolved problem with high

nighttime losses (see performance section). Any ideas for resolving the

performance problem, or improving the design would be most welcome.

Directory:

|

|

Goals

The Goals for this project are:

-

An efficient solar heater with

performance comparable to commercial units.

-

A long life with little

maintenance.

-

Four season operation in cold

climates *

-

Easy to build -- a weekend project

(well, maybe a long weekend)

-

Low cost -- less than $500 with all

new, high quality materials (much less if you have a good scrap pile, or

scrounge well)

-

Use only readily available

materials.

* This does not mean that it produces

100% of your hot water in the winter -- it would take a much larger

collector to do this. Nick would argue that the collector should be

made large so that it does meet nearly all your year round water needs, and that

is certainly possible.

Overview of the Heater

This solar water heater consists of:

-

An insulated pond that stores solar

heat (about 4ft by 8 ft and 11 inches deep on the prototype)

-

A pipe coil immersed in the pond

that your water flow through on its way to your heater. The water in the

pipe coil is preheated by the pond water.

-

A combination absorber and

insulating lid that absorbs solar energy. The insulated lid also reduces

heat loss from the pond.

-

A small solar electric pump that

pumps water from the bottom of the pond to the top of the absorber, where it

picks up heat and then drains back into the pond.

-

A glazed cover that is high on the

north side, and slopes down to the pond level on the south side. The

north, east, and west walls of the cover are reflectors to direct additional

sun onto the absorber.

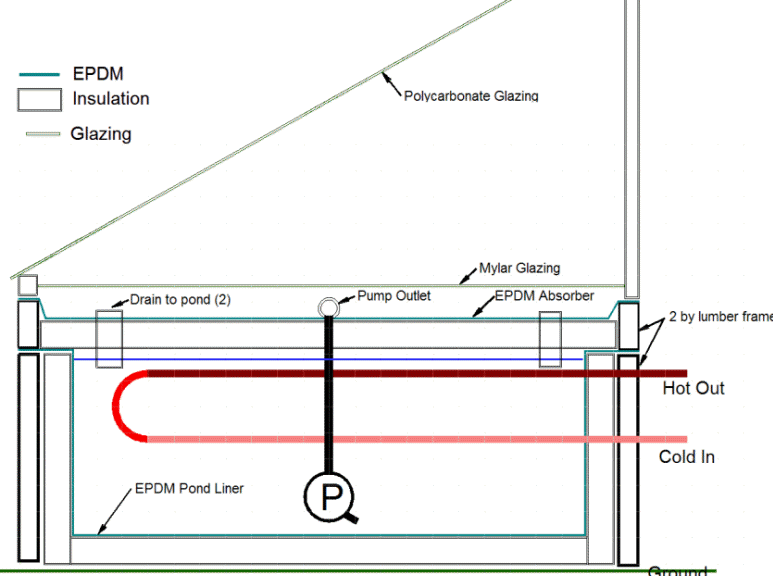

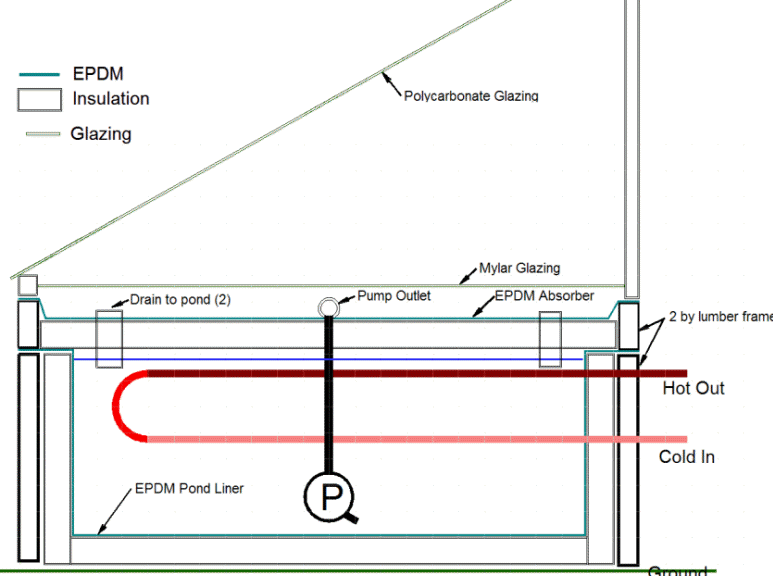

Schematic cross section of the solar

pond water heater.

The pond is well insulated, and lined

with an EPDM membrane for a long, leak free life. The prototype is

sized to meet a good fraction of the hot water demand for two people -- it can

be made larger to satisfy larger demands.

In operation, when the PV panel is

exposed to sun, it starts the pump up. The pump pumps water from the

bottom of the pond up onto the EPDM absorber. The water forms a shallow

pool on top of the EPDM that is about a half inch deep. The water heats up

as it flows around on top the absorber, and eventually this heated water finds

the drain that drains it back down into the pond.

When there is no sun, the PV panel

does not generate enough power to run the pump, and it stops. The water in

the pool on top the EPDM drains back into the pond. This leaves you with a

pond storing hot water that is well insulated, and has low heat loss.

When the house calls for hot water,

the initial water comes from the water that is already in the pipe coil, and is

up to the same temperature as the tank water. The coil itself holds enough

water that just the water in the coil will satisfy most single hot water

demands. For the prototype, the 200 ft of 1 inch diameter poly pipe

holds about 8 gallons. The coil can be made longer or larger in diameter

to hold more water if desired -- a 300 ft coil of 1 inch poly pipe might be a

good choice at 12 gallons. If more hot water is needed than can be

supplied by the water in the pipe coil itself, then the water is still heated as

it flows through the pipe coil, and the water coming out of the pipe coil

outlet will be preheated, but not up to the full pond temperature.

The pipe coil is acting as a heat exchanger to pick up heat from the pond.

The draw tests shows how this works for the prototype.

The final design will have a thermal

switch that will shut the pump off when the pond temperature reaches 140F.

This is to protect the black poly pipe pipe and the EPDM liner. This can be done with

a simple $10 thermal snap switch.

Potential Problems/Challenges

This is still and experimental

concept. Here are some known potential problems -- there may be other ones

unknown ones as well -- as always.

-

The High Density Polyethylene pipe

may not stand up to a combination of high pressure and high temperature.

It will definitely be at the limit of its intended use.

This is why the tank temperature must be limited to 140F (or so) with the

thermal switch.

I used the lowest pressure NSF approved PE pipe I could find (100 psi)

just to get an idea if this is a problem or not. Using higher pressure

PE pipe (160, or 200 psi) would provide more margin.

PEX or PEX-AL-PEX might provide somewhat more temperature capability than the

HDPE pipe, and would be a good candidate to try.

If all else fails, a shorter, smaller diameter coil of copper pipe could be

used -- copper is such a good conductor that the pipe coil would not have to

store a substantial amount of water.

-

The life of the EPDM absorber may

not be up to expectations, although it has been used successfully in this type

of application before. The EPDM pond lining should have a very good

life.

-

The small pump used in the

prototype will almost certainly not have a long life. One of the

remaining challenges is finding a small 12 VDC pump that pumps about 2 gpm and

will have a long life at 140F, and does not cost an arm and a leg.

-

One caution is that the pond is

filled with water that is hot enough to scald. The water is protected by

the glazing layer, and by the absorber/lid, but this is still a hazard worth

considering. If this is a concern, then using something like twinwall

polycarbonate glazing with good glazing supports might be one solution.

Construction

The construction is intended to be

simple, use readily available materials, and require no special tools.

The construction of the water heater

is covered here in detail.

Performance and Tests

The performance testing is

covered

here.

There is currently an unresolved

problem with high losses during the night (see the Day/Night test under link

above).

Any comments on this would be

welcome.

Comparing to Other Solar Water

Heaters

We may be a bit biased on this, since

we came up with this design in an effort to answer some of the short comings we

saw in existing solar water heaters, but here is how we see the tradeoffs.

Batch Water Heater:

Batch solar water heaters are a nice

simple design that can provide a high fraction of your hot water in warm

climates. They can also be used in cold climates, but must be drained for

the winter. Another shortcoming of this design is that the tank

temperature can drop quite a bit at night, because of the relatively high heat

loss out the glazing. There are some schemes that provide for night time

tank insulation, but these generally require that someone deploy the insulation

at night and remove it in the morning.

It can also be difficult to find a

good tank for the batch heater. If you can't find a used one in good

shape, then you pretty well have to buy a new water heater and strip off the

insulation and fittings to make a batch tank.

Our proposed design eliminates these

short comings at the cost of a bit more complexity, and few (not many) more

dollars.

Commercial Drainback and Closed Loop

Systems:

These systems work fine, have

relatively low maintenance, and a long life. But, they are expensive --

several thousand dollars. People into building things can

tackle one of these systems, but it is a fairly involved task, and the

components are expensive.

The goal of the new design is to

provide equivalent performance and life to these commercial systems at a much

lower cost.

Work on the earlier prototypes of the

solar pond water heater can be found here:

Gary 6/25/07

An

experimental concept for solar heating water that uses a pipe coil in a

glazed pond to collect energy.

An

experimental concept for solar heating water that uses a pipe coil in a

glazed pond to collect energy.