Search

The Renewable Energy site for Do-It-Yourselfers

Flow Organizer Solar Collector Test

|

This prototype of a window size solar collector with a

“flow organizer” grew out of an internet discussion on how to prevent excessive

heat buildup between an insulating window shade and the window glazing. Nick

Pine suggested that making the shade into some form of solar collector would

keep the heat from building up, and provide some useful heat to the living

space. Version one of this combined window shade and solar collector is here:

http://www.builditsolar.com/Experimental/ColShade/colshade.htm. Nick further

suggested that a version of the collector with a flow organizer might work

better than version one, which is a straight through thermosyphon collector.

This is a first cut at a flow organizer version of the window collector.

The results for a basic collector with flow organizer, and

the results of applying three refinements to this configuration are show below

in the “Test Results” section. The Flow Organizer collector appears to do quite

well. |

|

Solar Collector with Flow Organizer:

Most thermosyphon air collectors have an inlet at the

bottom and an outlet at the top. Cool room air enters the bottom, rises up

through the collector, heats up as it passes through or along the absorber, and

exits out the top vent.

This collector has a “flow organizer” that allows the cold

air inlet and hot air outlet to be positioned at the top of the collector. The

cold air passes between the aluminum sheet outlet vents and flows to the south

side of the collector (see picture). It then flows down the glazing, and

through the screen absorber, as the absorber heats up the flow, it rises up the

north side of the collector and exits out the aluminum outlet vents. The flow

organizer allows the cold flow to pass through the hot flow, and thus to flow

down the glazing. Having the cooler air flow down the glazing increases the

efficiency of the collector, by reducing losses. It also might be more

effective in preventing backflow at night.

There is a good description of the flow organizer on David

Delaney’s web site here:

http://davidmdelaney.com

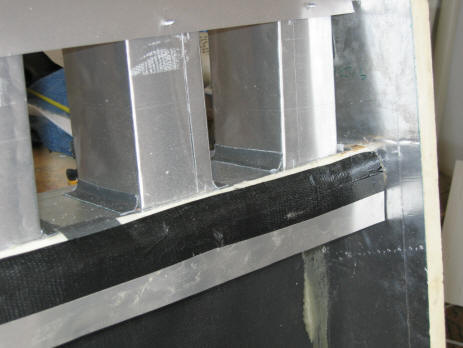

Flow organizer collector prototype viewed from the south

(sun side) without glazing. The rectangular aluminum ducts are the outlet

ducts. The cool incoming air flows through the gaps between the ducts, and then

down the glazing. It’s hard to see, but the absorber is a layer of window

screen suspended about midway back in the collector. The ¾ by ¾ piece of wood visible

near the bottom of the collector anchors the bottom of the absorber screen.

The flow organizer collector in position against an

existing piece of glazing.

The picture is taken outside, and is looking north (this is what the sun sees).

The 3 small aluminum cylinders shield the temperature sensors from direct

sunlight so that they can sense the air temperature (does anyone have a better

way shield the temperature sensor?).

Description:

Geometry:

Inside height from bottom to flow organizer shelf = 40.5

inch

Inside width = 40 inches

Height above flow organizer shelf = 6 inches (without flow deflector)

Collector area = (40.5 + 7)(40)/144 = 13.2 ft^2

Inside depth = 7 inches, 3.5 inches front of absorber

screen, and 3.5 inches behind screen

Inlet:

Inlet slot just north of glazing is 2 inches deep by 40 wide. Area = 80 sqin

Outlet:

6 outlet ducts at 3 inches wide by 4 inches deep. Area = 72 sq inches

The outlet ducts extend 6 inches above flow organizer shelf.

Temperature sensors:

There are 4 logged temperature sensors in collector.

All but the outlet temperature sensor are visible on the picture above.

Outlet temperature – centered in middle outlet duct.

Inlet temperature – in the inlet slot flow near middle of

collector and just below the flow organizer shelf. It is protected from the sun

by a 2 inch diameter alum cylinder.

Lower collector temperature sensors

Two temperature sensors are located about ¼ of the way up

from the bottom of collector.

One is just north of the glazing and the other is between

the absorber screen and the back wall.

Both of these sensors are protected from direct sun by aluminum cylinders.

Absorber:

The absorber is 1 layer of black fiberglass insect screen that is suspended 4

inches from the back wall (3 inches from the glazing). There is an open slot

of about 2.5 inches at the bottom of collector. Refinement 2 adds a 2nd

layer of absorber screen.

Walls:

The back wall of collector is 1 inch Polyiso insulation board, and is painted

black on the inside.

The other walls and bottom are Polyiso board without

paint. They are faced with aluminum foil.

Test Results --A base configuration and 3 variations on it were tested.

The table below gives a summary of the results.

Base Collector: has one layer absorber screen, no

flow deflector, square edge on inlet flow

Variation 1: added a deflector that was aimed at

deflecting the flow from the outlet ducts into the room. The deflector did seem

to increase the output noticeably (+15% ish). I’m a bit at a loss to explain

why this made so much difference.

Variation 2: added a 2nd layer of

absorber screen. This actually appears to lower the output. The flow rate is

down, and the delta T from inlet to outlet is about the same.

Variation 3: added rounding of the corner on the

flow passage into the inlet slot. That is, rounding the south edge of the flow

divider shelf. The area of the inlet slot was not changed, but instead of

having a sharp corner where the air turns down into the inlet, it was rounded

off. This does not appear to make much difference. It actually shows a slight

reduction in output, but I think that is just the error margin in the test

setup.

The night measurements seem to indicate that not much air

is flowing through the collector, which would be good. I could not detect any

flow velocity, but I can’t really read any less than about 60 fpm. Smoke would

be nice.

Results Table

|

Parameter |

Base

(1) |

Add Deflector (2) |

Add 2nd Screen

(3) |

Round Inlet Lip

(4) |

Night

(5) |

2/01/06 Dave's

Changes |

2/10/06 2nd with

Changes |

|

Time |

10:00 am |

11:30 |

12:24 |

12:56 |

12 midnt |

11:02 |

11:41a |

|

Tambient |

33F |

38 |

40 |

40 |

? |

42 |

30 |

|

Troom |

63 |

69 |

73 |

76 |

? |

70 |

64 |

|

|

|

|

|

|

|

|

|

|

Tinlet |

75.5 |

88.1 |

92.9 |

91.8 |

42 |

91.0 |

87.1 |

|

Tglass side ¼ up |

95.4 |

111.1 |

127.6 |

123.2 |

28 |

|

98.0 |

|

Tback side ¼ up |

91.3 |

114.7 |

112.7 |

110.9 |

30 |

|

110.1 |

|

Toutlet |

107.0 |

124.3 |

129.2 |

126.8 |

47 |

121.6 |

117.8 |

|

Tglaz(10) |

|

97/78 |

109/84 |

101/76 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Voutlet |

90 fpm |

100 |

90 |

90 |

|

105 |

100- |

|

Vinlet |

70 fpm (9) |

80 |

70 |

75 |

|

85 |

80 |

|

Sun |

18500 lum/ft^2 |

20500 |

21000 |

20500 |

0 |

20500 |

21500 |

|

|

|

|

|

|

|

|

|

|

Tout-Tin |

31.5F |

36.2 |

36.3 |

35 |

5 |

30.6 |

30.7 |

|

Qout |

1897 BTU/hr |

2422 |

2186 |

2108 |

0? |

2150 |

2054 |

|

Qout adj |

2153 |

2481 |

2186 |

2160 |

|

2203 |

2006 |

|

Qout/sqft |

163 |

188 |

166 |

164 |

|

170 |

154 |

Configurations:

(1) Base

configuration as described in the geometry section above. One absorber screen.

(2) As above, with

added alum sheet deflector that deflects the heated flow from the outlet ducts

toward the room (see picture).

(3) As above, with

another layer of window screen added to the absorber – 2 layers total.

(4) As above, with

the south edge of the flow divider shelf rounded to improve inlet airflow.

(5) Same as

configuration 4, but run at night.

Base Configuration Energy out (Qout) was calculated as:

Qout = (107F – 75.5F) (0.715 ft^2)(90 ft/min) (60

min/hr)(0.065 lb/ft^3) (0.24 BTU/lb-F)

= 1897 BTU/hr

Adjusted Energy Out (Qout adj) is the energy out adjusted to the highest sun

level of the test. This is an attempt to compensate for the fact that sun

level varied throughout the test. Sun level was measure with an Onset light

intensity logger, which gives light intensity in lumen per sqft. It does not

measure the full solar spectrum, but does give some idea how much the sun varied

(see plot below).

Update 2/14/06:

This test incorporates the changes suggested by David.

The changes are:

-

Add a vertical flow divider that extends vertically down 2 inches from

the edge of the horizontal flow organizer shelf.

-

Move the absorber toward the north (now 3 inches from back and 4 inches

from front)

-

Terminate the absorber 5/8 inch below the bottom of the flow organizer

shelf

-

Suspend the absorber from a horizontal wire such that the top of the

absorber does not have a “fat” support that impedes flow.

-

Also went back to one layer of absorber screen, since this seemed to work

better in earlier test.

-

Dave’s drawing below:

Pictures with the changes:

Vertical flow divider added.

I am wondering if I should have used a light colored tape?

The tape gets hot the touch, and may be discouraging the downward airflow at the

inlet by heating it to early?

Looking up at top of absorber, and into the outlet ducts.

The absorber has been moved north a bit, and the thick member at the top of

absorber replaced by a suspension wire with tape over it.

Single absorber screen.

How did the Flow Organizer Collector compare with

others:

A VERY rough comparison of the outputs of several air collectors:

The Collector Shade concept (1) 100

BTU/sqft-hr

The Organized Flow collector 190

BTU/sqft-hr

The Garage Thermosyphon collector(2) 230

BTU/sqft-hr

(1)

shade converted to thermosyphon collector:

http://www.builditsolar.com/Experimental/ColShade/colshade.htm

(2) My workshop

thermosyphon heater:

http://www.builditsolar.com/Projects/SpaceHeating/solar_barn_project.htm

It may be unfair to compare the garage collector to the two window collectors,

as it has the advantage of a 7 ft rise from inlet to outlet.

From outside with aluminum sheet flow deflector in place.

It deflects outlet duct flow into room.

With the inlet lip of the flow divider shelf rounded off to

allow smoother flow into inlet slot. It turns what was a square edge into

a half cylinder. It actually looks better than the

picture. Looking northwest. Screen absorber starts just below the

white south edge of flow divider shelf.

Odd stuff:

It seems odd that the collector inlet temperature was so much higher than room

temperature. Typically there was an about 20F difference between room temp and

the sensor that measured the temperature right at the top of the inlet slot. Is

the inlet air getting warmed by the outlet ducts or air before it gets to the

inlet slot? Or, is the temperature sensor not getting a good reading? The

area of the inlet temp sensor is in sunshine. I surrounded the temp sensor with

an alum sheet cylinder to shield it from the sun – maybe the shield is not

effective? Any ideas on this?

I added the flow deflector to see if that would decrease

this difference between room and inlet temperature, but it actually increased

it, and also increased the output – odd.

Looking at the temperature sensors that were located about

¼ of the way up from the bottom of the collector. One is near the glazing, and

the other half way between the absorber screen and the back (north) wall. On

most of the tests, the front sensor reads higher temps than the back sensor.

This seems like the wrong way round?

Both of these sensors are in the sun, but are shielded by

the same kind of cylindrical alum shields described above. Any ideas on this?

Adding the 2nd layer of window screen absorber seems to increase this

effect.

Cautions:

I have to say this was a start, but not done to the level of precision I

would like, and I think the numbers should be used with some caution. It would

be nice to do more of a side by side comparison under exactly the same sun

conditions, and I am not sure I believe that the temperature sensors in the flow

organizer collector are measuring the actual air temperature even with the

shields. I pass the results on because they seem interesting, and maybe someone

will want to take this further, or make some suggestions on how it could be done

better.

2/14/06 -- after playing around some more with the

temperature sensors, and doing some additional measurements with a shaded

thermocouple on a stick that I could move around from place to place, I feel

better about the temperature sensors getting fairly accurate data for both of

the tests.

Gary

1/28/06

Updated 2/14/06

Data Logger Plots:

Configuration 2 -- Base configuration with outlet

deflector added:

Configuration 3 – outlet deflector + 2nd

absorber screen:

Sun Intensity:

Update 2/14/06 -- logger plot for the flow organizer

with Dave's suggestions incorporated:

2nd Test with changes 2/10/06

Some Construction Pictures:

Geometry:

Overall height

48 inches

Height from bottom

to flow organizer shelf 42.5 inches (40.5 inches inside)

Overall width 42

inches (40 inches inside)

Overall depth 8

inches (7 inches inside)

Depth of cold air

entry slot 2 inches

Window screen

divider is 4 inches for the back (north) face and 3 inches form the front

(south) face.

Area of downflow

channel = 40*3 = 120 sqin

Area of upflow

channel = 40*4 = 160 sqin

Upflow vents (hot

air exit) -- 6 total at 3 inches wide (E-W) by 4 inches deep (N-S) -- 6

inches tall.

Upflow vent area =

(3*4*6vents) = 72 sqin -- about 50% of upflow channel XC

Slots between the

upflow vents (where cold air enters) are 3.66 inches wide.

Area between

upflow vents = 5* ( 2*1.83 + 5*3.66) = 110 sqin -- about 90% of

downflow channel XC

Sides, bottom, and back are made from

1 inch Polyiso board with alum foil faces. South face of back wall is

painted black using barbeque paint. Glued together with "great

stuff" PU foam.

The flow divider board is also 1 inch

polyiso -- it has 6 rectangular holes of 3 X 4 inches each to accept the

alum upflow vents. The slots between the upflow vents are 3.66

inches wide.

The upflow vents are made from light

alum flashing bent into rectangular 3X4 inch ducts. The ducts stick up 6

inches above the flow divider board after being pushed fully into the flow

divider board.

The vertical screen is one layer of

black fiberglass window screening. The top end is fastened to the flow

divider board at the S margin of the upflow ducts. The bottom is weighted

with a 3/4 by 3/4 wood piece, so that it hangs vertically. The bottom of

the screen is about 1.5 inches above the bottom of the enclosure.

My intent is to just push it against

one of the acrylic panels on my outer garage doors to test it.

I will put some of the Onset

temperature sensors in the up and downflow paths.

If the velocity if high enough, I'll

measure it with the Kestrel meter or the Testo stick.

It would be nice to have some way

(like smoke) to see the flow -- I have not had much luck with generating enough

smoke to be useful -- maybe you have an idea on this.

I did not glue in the ducts or the

flow divider board so that they could be changed easily.

Not sure what to do about the top lid

for the box (near the top of the upflow ducts) -- if anything?

I'll give it a try on the next sunny

day -- which may be tomorrow -- let me know if you have any ideas on things to

change or measure.

Flow divider board

Cut out with razor knife -- very fast

and clean

Upflow duct from alum flashing.

Upflow ducts taped to flow divider board.

Bottom of screen-- looking north.