Search

The Renewable Energy site for Do-It-Yourselfers

A Test of Reflective Surfaces In Front of Vertical Solar Collectors to Improve Performance

|

Vertical solar heating collectors have a lot of advantages: They integrate easily with existing walls, they perform very well in the winter when the sun is low, and they have little tendency to overheat in the summer.

Vertical collector performance does tend to fall off as the sun gets higher in the sky in the summer. In most cases, the fall off in mid summer is fine in that its sunnier, warmer, and the heat demand is lower. But, in the late spring, when the sun is getting higher in the sky, and the heat demand can still be high can the fall off in heat output can be a problem. This is especially true in cold climates with long winters.

This page looks at a test of several reflective surfaces that can be placed on the ground in front of the vertical collector to improve its performance. The surfaces tested include:

- A black surface (the baseline for the other surfaces)

- White rocks

- A white painted panel

- A specular Aluminized Mylar reflector

A test was done comparing each of these surfaces in front of our $2K vertical collector in mid summer. The details are shown below.

The quick bottom line is that white rocks show a modest improvement, a white painted horizontal board shows a better improvement, and the aluminum reflector shows an even better improvement, but requires more careful installation.

All of these results will vary some depending on time of year and the detailed geometry of the collector and reflector -- see below for more.

|

|

The Setup

At our 46 degree latitude in mid summer, the noon elevation angle of the sun is nearly 70 degrees, so the solar incidence angle on a vertical collector is only about 20 degrees. This reduces the effective area of the collector.

The effective area of the collector is reduced by the cosine of 70 degrees, or about 0.34 of what it is when the sun is shining directly on the collector (as it is in the winter). This is typically not a problem in mid summer, when the only heat demand is for domestic water heating, and the weather is sunny and warm. But, in late spring with the sun getting higher in the sky, and heat demand still fairly high, something to prevent the fall off is desirable.

Several reflective surfaces were tried in front of the vertical solar space and water heating collector.

The test was done in mid summer (July 3-4) at a latitude of 46 degrees, so the sun's elevation at noon is nearly 70 degrees (only 20 degrees short of directly overhead). The collector is vertical, and is oriented about 10 degrees east of due south. I did the test when the sun was directly facing the collector.

The day was nearly clear with occasional very high thin clouds drifting through. I kept the measurements to the clear periods. At the start end end of each run I measured the sun intensity on a reference surface that was nearly normal to the sun and that did not change during the test -- the small changes in radiation on the reference surface were used to correct the readings on the glazing. The test started at 11:56am local time and went to 1:03pm local time. The section at the very bottom of the page shows the logger plot for a couple of the runs.

The reflector boards/surfaces extend out about 4 ft out from the collector.

I only took radiation measurements up to 6 ft on the vertical collector, as the shadow from the eve comes down below 7 ft at this time of year.

The solar intensity was measured with an Apogee pyranometer at each of the locations marked by painters tape in the picture above.

The pyranometer was mounted on an extension handle so that I could take the readings without interfering with the reflected light.

The surfaces tested were:

- A black surface used as a baseline for the others

- White marble rocks in front of the collector

- A white painted insulation board tilted slightly up

- A white painted insulation board tilted slightly down

- An Aluminized Mylar foil on a rigid board

Black Cloth

The first run is with black weed cloth over the white rocks to give a baseline with little to no reflected light.

So, this gives a baseline value with very little reflection. It might be pretty close to bare earth or dark rocks, but likely reflects a bit less than (say) grass.

White Rocks

The rocks are white marble chips from Lowes.

The white rocks are just sprinkled over the old grey rocks until the surface appears uniformly white. The rocks are mostly a spouse beatification program, and not really related to improving the collector performance.

The nice things about the rocks:

- They do look nice

- They do reflect some useful light onto the collector (see results)

- No maintenance? Maybe hose them off once in a while.

- Easy

- Not expensive

I guess that one negative would be that if you put plants in the rocks, and they get large, they will reduce the gain.

White Painted Flat Surface -- Up and Down Tilt

A sheet of 1 inch polyiso insulation board I had lying around was painted with white satin paint to make a reflector. The face sheets on the insulation board are flat and relatively smooth -- not a lot different than a sheet of plywood.

I tested the white board twice -- once with the south end tilted down, and again with the south end tilted up. The results chart below shows both tilts.

|

White painted board with 7.8 degree downward tilt to south.

|

White board with 7.5 deg upward tilt to south.

|

The white board definitely increases the radiation on the bottom half of the collector.

Compared to the aluminized Mylar reflector, the effect does not depend much on the up or down tilt of the board. I think that horizontal would be fine.

The nice things about the painted white board:

- Simple and effective

- The tilt angle of the reflector does not appear to be critical to getting good performance.

- Lower maintenance and cheaper to maintain than the aluminized Mylar reflector.

I would guess that if you have snow in front of the collector in the winter, the benefit of the snow is at least as much (probably a bit more) than these white boards -- so, don't shovel the snow in front of your collector :)

Gloss paint might have worked better, or been more of a specular reflector.

Aluminized Mylar Reflector

Aluminized Mylar film was taped to the top surface of the white board for the highly reflective material test.

The reflector board is tilted 7.5 degrees upward to the south (south end is higher).

The tilt angle is more critical with the aluminized Mylar, as the reflection is much more specular. For example, if the reflector is tilted 7.5 degrees down to the south, the bulk of the reflection misses the collector and lands on the roof soffit. But, in the winter, the downward tilt would be more optimal. So, for this reflector, the tilt angle would want to be adjusted seasonally for best effect.

This is the only reflector in which the reflected pattern of light on the collector is clearly visible.

The mirror that is placed on top the aluminized Mylar was used to reflect into the area where the reflected light measurements were taken. The aluminized Mylar has enough ripples in it that it does not give consistent reads (you can see this in the reflected pattern on the house siding). The mirror is flat and gives good consistent readings.

The nice things about the aluminized Mylar:

- Best improvement by a pretty good margin

On the negative side, getting the tilt angle right is important and changes with season, probably higher maintenance, and probably not an aesthetic plus for most people.

Summary of Results

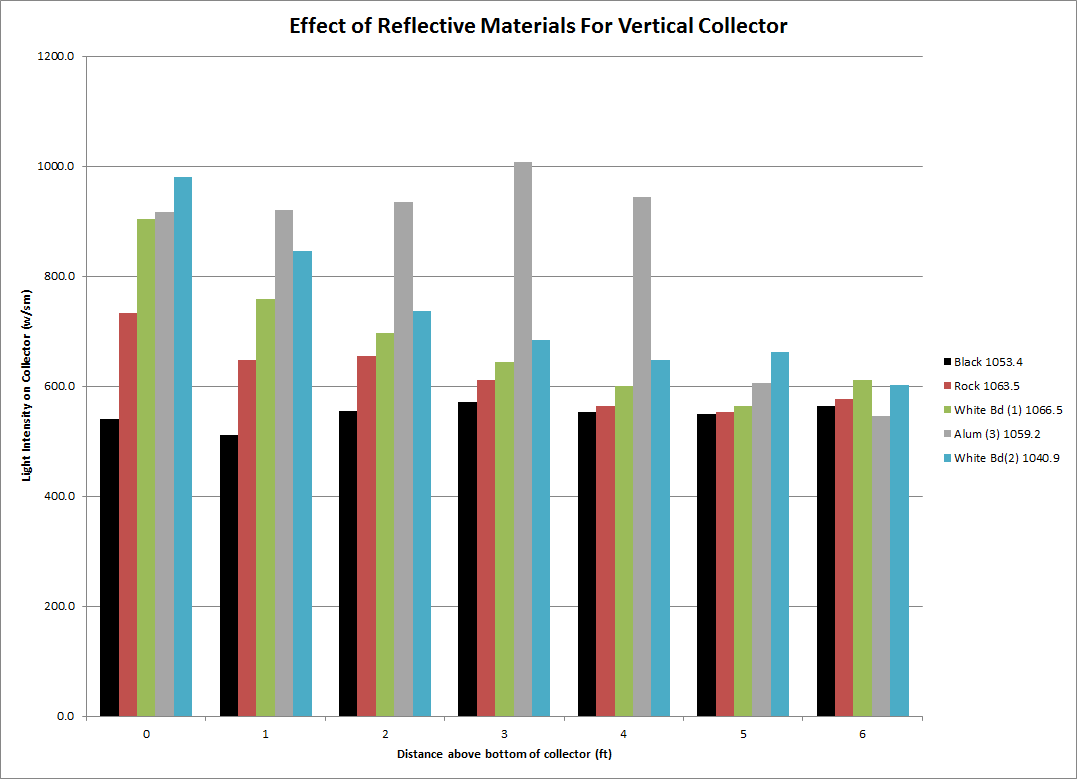

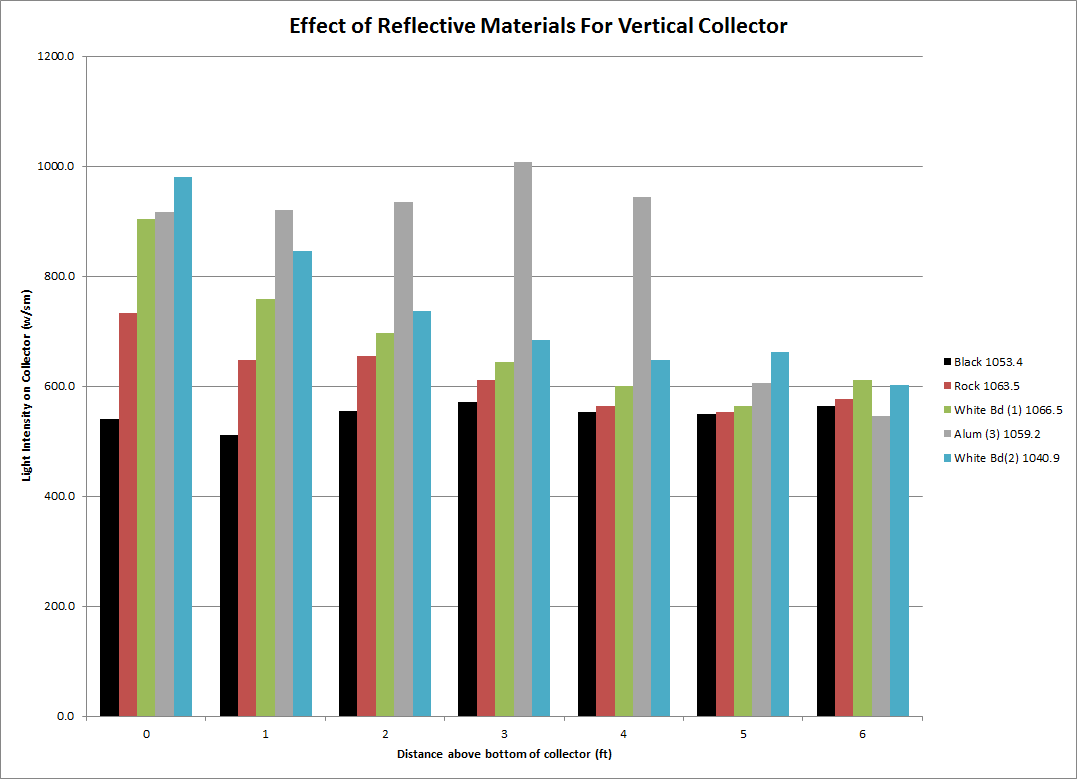

The plot compares the radiation levels on the collector glazing at 1 foot intervals starting at the bottom of the collector. The locations are the squares of blue tape that show on the pictures above. Radiation is is in watt/sqmeter. The pyranometer is oriented facing outward (perpendicular to the glazing).

The bars are:

Black -- A black weed fabric laid out on the ground in front of collector

Red -- White marble rock in front of collector

Green -- A flat board painted satin white extending out 4 ft, and sloped down to south at 7.8 degrees

Grey -- Aluminized Mylar film laid on top of the white painted board and sloped up to the south at 7.5 degrees

Blue -- The same white painted board sloped up to the south at 7.5 degrees

Some thoughts:

The table gives the increase in performance of the collector for each material. This is estimated by comparing the total of the black fabric readings to the total of the readings for each material. The gain in heat output might be somewhat better than what you would get by increasing the area of the collector by the same factor, as the reflector increases the heat input to the collector without increasing the glazing area and glazing losses.

| Material |

Benefit |

| Base (black fabric) |

1.0 |

| White Rocks |

1.13 |

| White board (7 deg down) |

1.24 |

| White board (7 deg up) |

1.34 |

| Aluminized Mylar |

1.53 |

All the reflectors extend out about 4 ft in front of the collector, and the benefits extend up about 4 ft up the collector. A reflector that extends further out would likely provide more benefit on the top half of the collector. The tables in the Reflector Section address this.

Comments

If you have any thoughts, comments, corrections on this, please leave them here...

See the Reflector Section for more info on using reflectors to improve collector performance...

Gary

July 5, 2013