Search

The Renewable Energy site for Do-It-Yourselfers

Solar Collector -- Small Panel Test

-- Conductive Silicone

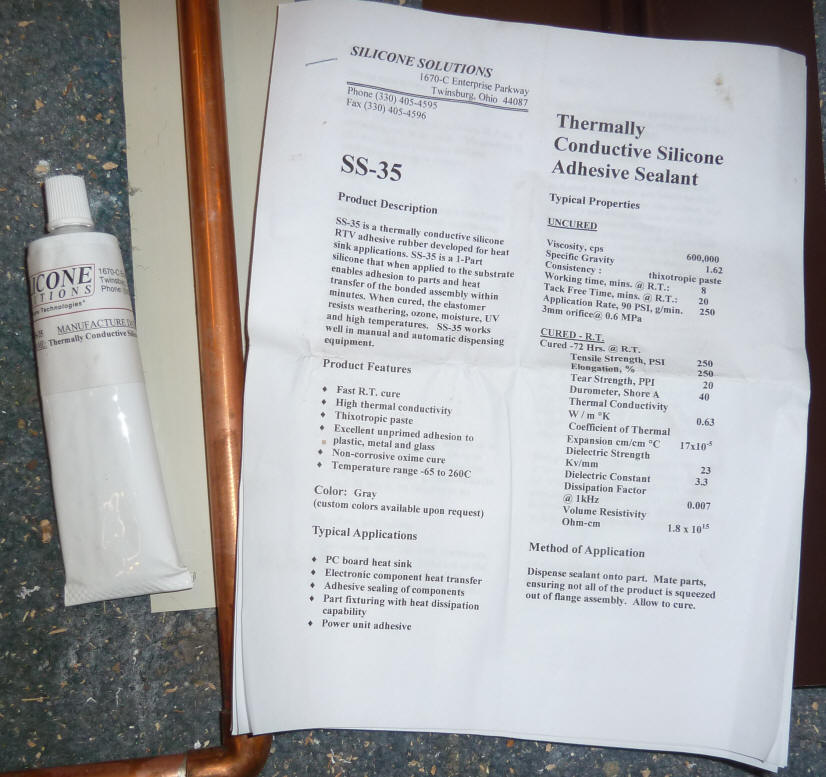

The conductive silicone I used is made by Silicone Solutions -- this is the

data sheet:

The specification sheet for the high conductivity silicone. The thermal

conductivity is about 3 times greater than regular silicone caulk.

This shows the absorber with the conductive silicone caulk before it was painted

black.

This shows the copper tube to aluminum fin joint with the silicone fill.

The critical thing is to keep the gap paper thin.

It does not show in the picture, but there is a 3 inch wide strip of flat

aluminum just under the tube and aluminum fin. To assemble the fin, a

small bead of the silicone is placed in the fin groove, then the fin is clamped

very tightly onto the copper tube, then while still clamped, the grooved

aluminum fin is screwed to the underlying 3 inch wide flat piece of aluminum.

See

here for details on the assembly...

This shows the 3 collectors each heating its own reservoir.

The two collectors are as identical as I can make them except for the

differences being tested -- in this case one with regular silicone caulk

between fin and tube and the other with conductive silicone caulk between tube

and fin. The third collector is the baseline copper tube soldered to

copper fin collector that is included in all tests.

The water reservoirs are of identical size and construction, and the water

charge is weighted into each of the reservoirs to insure that they start with

equal amounts of water. The temperature of each reservoir is logged, and

the performance of each collector is in direct proportion to the amount it is

able to heat its reservoir during the test.

The plot shows the results for a 3 way side by side by side test of:

1 -Black solid line: A reference collector with copper

risers soldered full length to copper fins.

2 -Red dash line: A collector made with copper risers and

aluminum fins with regular silicone between fin and riser

3- Green long dash line: A collector made with copper

risers and aluminum fins with a conductive silicone between fin and riser

The conductive silicone shows a temperature gain that is 0.5% better than the

regular silicone. This is a pretty small change and may well be just

experimental variation.

So, based on this, I would say that its not worth going to much of any extra

trouble to find a conductive silicone caulk.

Gary May 26, 2011