Search

The Renewable Energy site for Do-It-Yourselfers

Try a Collector

Made From EPDM Rubber Sheeting

|

was going to make the

collectors for the Solar Shed by buying

conventional, pre-made absorbers (copper tube risers with copper fins), but

after reading David Mears description of the the very simple collectors they

made for heating greenhouses, I got to wondering if I could do a collector that

has most of the simplicity and cheapness of the Mears collectors, but with

better durability and a longer life.

The collector would

go

on the open

face

of this storage

shed, with

hot water piped to

the house for space

heating.

|

|

I

The design I am thinking about has

two sheets of EPDM rubber that form the absorber. The water to collect

heat from the absorber would flow between the two sheets. The water would

be fed in at the top via a manifold, and collected at the bottom via a pipe or

gutter. The collector would be glazed with twinwall polycarbonate glazing

panels. The potential advantages of this are that 1) the materials would

cost less than half as much as the conventional collector absorber, 2) it would

be simple to make, 3) its pretty forgiving for freezing (it might survive a

failure of the draindown system), and 4) it seems to me it should have just

about the same efficiency as a regular flat plate collector(?).

It seemed like the most challenging

thing in this design is to get the water to flow uniformly between the two

sheets of EPDM, and to fully wet the back side of the front sheet. The

front side (south side) of the front sheet receives all of the solar input.

The water flow along the back of the front sheet must remove the solar heat

uniformly over the full sheet. If it does not, parts of the EPDM sheet

will overheat, which will lead to a shorter life and higher loses.

I set up a little test fixture to try

to see if I could get the desired uniform water flow over the full EPDM sheet.

The plywood and 2X4's support the

sheet of EPDM at the same 70 degree angle they will be in on the solar shed.

The water is pumped out of the orange bucket by a small submersible pump in the

bucket at 1 gpm. The water is distributed to the EPDM sheet by the white

plastic pipe, which has 1/16th holes drilled on 2 inch intervals. Normally

the manifold would be at the top of the sheet, but I lowered it for the test

just to make it easier to reach.

This picture shows jets of water

coming out manifold -- 1 gpm total over the 4 ft width. One gpm per 4 ft

is about what the flow will be on the real collector in order to remove the heat

with a no more than 10F temperature rise.

I did this first series of tests with

just one sheet of EPDM so that I could see how uniform the flow is.

Try 1: Just let the water flow

down the EPDM sheet and see how uniform it is:

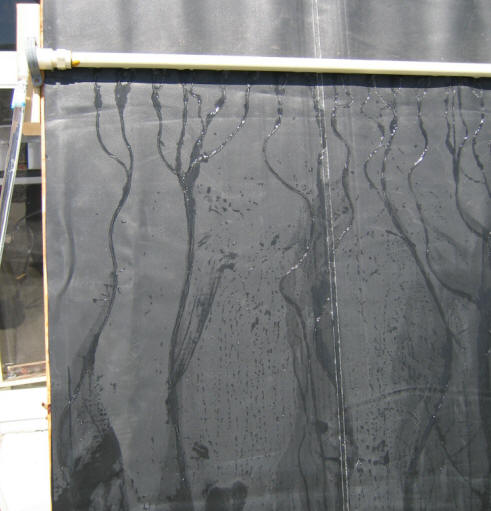

The water does not spread out

uniformly, but stays in little streams that wander around, and sometimes join up

to form a larger stream. After a minute or so, a stable pattern emerges,

and only a small percentage of the sheet area is wetted. Surface

temperatures are around 40F near the streams, and up to 90F between streams.

So, this does not work very well.

(all these temps are too low, as

something seems to fool the IR temp meter, but the differences are probably

pretty close).

Try 2: Add Detergent

I tried washing (scrubbing) the EPDM

surface with a water/detergent solution, and tried adding detergent to the water

in the bucket.

This is with detergent in the water.

It straightens out the flow streams, but does not spread the water out into a

uniform film.

Try 3: Add a sheet over the back

sheet

I added a sheet of clear Vinyl over

the EPDM sheet to see if the flow would spread out between the two sheets.

Hopefully, the Vinyl acts pretty much

like the front sheet of EPDM would act, but allows you to see the flow(?).

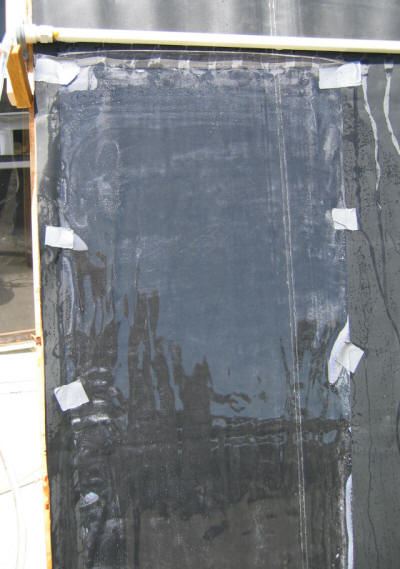

This is the clear Vinyl shortly after

it was put on. There is no detergent in the water.

Its a little hard to see in the

picture, but, while the Vinyl spreads the flow a little, it is still highly

channelized.

The light areas are small air bubbles

that start to form under the Vinyl almost immediately.

The area at the top of the sheet has

more uniform flow because I ran my hand over it.

Try 4: Squeegee the Vinyl sheet

I ran a block of wood over the full

surface of the Vinyl sheet to force it into contact with the back EPDM sheet.

As you can see from the picture, this

makes for much more uniform flow. There is still some temperature

variation where the Vinyl pulls away just a bit from the EPDM. but much better.

The temperature variation is about

10F from the coldest to hottest spots.

This is taken right after the

squeegee.

Within a short time, the white areas

on the picture to the right start forming. These are small bubbles.

Not sure that these have any bad

effects, but it does not seem like a good thing?

So, this has a bit of promise, but

the fact that it takes the squeegee to get the uniform flow started is a

problem. It would be a pain to have to go out and squeegee your collector

on each startup :-)

Try 5: Add a Shade Cloth Layer Over

the EPDM

This is what Mears used to even out

the flow over his PE plastic absorber.

Its

a bit difficult to see in the picture, but this does have a somewhat beneficial

effect.

Its

a bit difficult to see in the picture, but this does have a somewhat beneficial

effect.

You can see in the picture that the

flow off out the bottom of the shade cloth is more uniform.

Its a bit hard to see, but there is

still some channeling, and, while the temps are fairly uniform, there is still

some variation.

The channeling tended to get a bit

worse as time went on.

I tried putting the layer of Vinyl

over the shade cloth, and it worked poorly.

It seems without something to push

the Vinyl against the shade cloth, the flow on the back of the Vinyl sheet is

only in contact with a small part of the shade cloths (and water).

The Mears collector is basically like

a two skin greenhouse with a very low air pressure between the two skins.

This air pressure tends to compress the absorber layer, shade cloth layer, and

top skin together -- this may make for more uniform flow.

Try 6: Try a Finer Weave Material

Instead of Shade Cloth

I thought that the coarse weave of the shade cloth might be responsible for

the non-uniform flow, so I tried a piece of weed fabric that is more pliable and

has a finer weave. Its a bit hard to see the cloth, since its the same

color as the EPDM, but if you look closely, you can see the bottom edge.

This worked poorly. The streams from the manifold just went straight

down the fabric with no spreading.

It gets somewhat better if you squeegee it out.

So, this is not working so well yet.

None of the tries results in a

uniform flow of water over the full surface of the EPDM being established

automatically.

It seems even less likely that when

the top sheet of EPDM (which is the actual absorber) is added that the flow of

water will be in uniform contact with it.

Thoughts:

The idea of using two sheets of EPDM

is that the heat transfer water is kept between them, and the cavity between the

top EPDM sheet and the glazing is dry.

If you went with one EPDM sheet with

water flowing on the sun side, then the glazing would be exposed to hot moist

air, and condensation on the glazing would reduce efficiency. The

polycarbonate glazing may not hold up to these conditions.

An alternate would be to have a film

type of glazing over the EPDM to separate the water from the PC glazing.

This would still require a way to

make water flow uniformly over the EPDM (maybe doable), and would also require a

film glazing that would hold up well.

A somewhat similar setup would be to

go with corrugated metal siding similar to the Thomason collector, but with the

film glazing.

About 9/06

3/29/07 note -- getting the water to

spread out more evenly would be easier with a lower tilt angle.

--------

Summer 2007:

Did a little more work on this with

other materials over the EPDM to spread the water.

Placing an ordinary cotton bath towel

over the EPDM works nearly perfectly.

Bed sheet material also works pretty

well -- not as good as the towel, but good.

So, perhaps fabrics that take water

into their fibers work best?

Gary Dec 6, 2007