Search

The Renewable Energy site for Do-It-Yourselfers

Barra Box --

Change Package A Changes

Change package A included these

new items and changes:

- Add a backdraft damper mounted in

the intake of collector inlet duct just below bottle shelf.

- Add insulation to east, west, and

north walls (not done yet) (1.5 inch polyiso, non-relfective). (now done

Jan 19)

- Add more bottles to fill up the

bottle shelf (now 3 rows of 18 2 litre bottles).

- Remove the external insulation

panel covering the top 7 inches of the collector glazing, and change to the "V"

box arrangement inside the collector (see below).

- Add support for the screen absorber

top and bottom to allow the screen to be fastened better and to position it more

precisely.

- Add support along the top of

glazing and a vertical support in the middle of the glazing to keep it from

bowing inward and to allow better sealing.

- Add temp sensors to first and last

row of bottles rather than just the middle row.

- Add a port on side of collector and

light inside collector to allow the backdraft damper to be observed, add the

duct air velocity to be read through the port on the side.

- Add a seal strip around the top of

the box to provide a flat surface for the lid to sit on.

- Add motor on/off logger to the fan

to allow fan on time to be logged.

- disconnect the bottle temperature

thermal snap switch as a fan control --fan is now controlled only by room temp.

- Generally improve the sealing for

air leaks all around.

- Sprayed some more black paint on

the absorber.

- Replaced the "room" thermostat,

which was not working (Jan 19)

Some Discoveries on Opening the Box

to Install the Change

Many of the bottles had leaked some

of their fluid out. The ones with plain water were OK, but most of the

ones with Cola, Sparkling Water, and Tonic Water had leaked -- some quite a bit.

It appears that all the leakage was

around the bottle cap, and not due to a failure of the bottle itself.

Some of the bottles that had pushed

out some of their fluid. Also tend to bulge the bottoms out.

I refilled all the bottles that were

not plain water and reused them.

Now have 3 rows of 18 bottles each.

Thermometer at top of collector (just

below bottle shelf) did not fair so well.

The tube was lying broken at the

bottom.

Changes to Collector and Glazing

Added a wood bar about 7 inches down

from top of glazing to support the new "V" box at top of collector, and a

vertical glazing support in the middle (the EMT conduit).

These are both to support the new "V"

box and to keep the glazing from bowing in so much.

Added a wood strip along the bottom

of the absorber (clamps hold it while foam glue dries). This is to have

something solid to staple the black screen absorber to.

This shows the new "V" arrangement at

top of collector -- Nick's idea to get some useful heat out of the top few

inches of collector without losing a lot of heat from the bottle shelf area at

night.

Single layer of screen absorber

stapled in place between the new wood strip at bottom of absorber and the new

wood strip at bottom of the new "V" near top of collector.

The screen was later stapled under

the top wood strip so that at the top of the screen, it is about half an inch

from the glazing. So, flow path is: air enters bottom of collector between

the glazing and the screen. Air rises up through the screen, and

exits the collector at the top behind the new "V" board and then North into the

bottle shelf.

New Insulation on Collector Inlet Duct

Added new insulation boards on the

south and north sides of the north wall of the inlet duct. There are two

boards, each is 1 inch polyiso -- non-reflective.

Also sealed all the floor to wall and

wall to wall joints with Great Stuff on inside of box.

Backdraft Damper

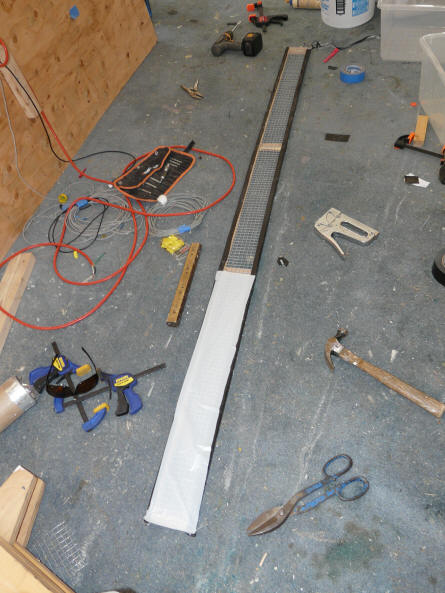

This is the framework for that holds

the backdraft damper. The top part shows the half inch hardware cloth used

to back up the poly film.

Bottom part is getting the poly film.

This backdraft damper frame sits on

top of the inlet duct north wall, and is oriented to allow north to south

flow, but stop south to north flow.

The backdraft damper does not seal

perfectly against backdrafts -- there are very small gaps and cracks around the

edges in places, but it looks pretty good to me. It gets pulled against

the hardware cloth backup as soon as the sun goes off the collector.

Backdraft damper installed on top of

the inlet duct wall before the bottle shelf is installed over it.

Note the Dwyer Van Meter installed

near the middle.

So, air flow under the bottle shelf

northward through the poly film backdraft damper, and then down the inlet duct,

then under the absorber from north to south, up the south side of the absorber.

When it reaches the top of the absorber, it flow north over on top of the

botttle shelf through the bottles.

Collector in operation.

Backdraft damper poly film blown out by entering air. Vane meter reading

just under 50 fpm -- probably would be right at 50 if the vane meter were level.

This picture is taken through the

hole in the side of the box shown just below.

Hole cut in side of collector to

allow the performance of the backdraft damper to be observed.

A light is mounted just below the

hole and inside the collector to light the damper and the vane meter.

The hold is plugged with the hole saw

cutout when not taking pictures.

Bottles

3 rows of 18 2 liter pop bottles

installed on top the bottle shelf.

Also new wood seal strip all the way

around the top of the walls and glazing to make a flatter surface for lid to sit

on -- these are sealed/glued to top of walls with Great Stuff.

Bottle temp sensors taped to south

row (at black tape), and to north row. Sensor is positioned at the side of

bottle where it contacts the next bottle.

Fan inlet is just visible to left.

The snap disk thermometer switch to

left in foreground is not currently used, but could be used to keep the fan from

turning on when the bottles cool below some set temperature.

For the initial setup, the fan is

unplugged just to give the bottles some time to warm up.

This shows the thermostat in the

middle of the "living room". It is set to about 65F.

The logger sensor that records roomt

temp is the black taped gadget on the grey wire.

Both are about half way down into the

living room.

The collector inlet duct with

backdraft damper is visible at the top of picture.

The fan outlet is also visible.

The small crack between the inlet

duct wall and the floor is calked from the other side.

Looking up into the fan outlet with

the motor on/off logger mounted on the end of the fan motor.

Added Insulation

On Jan 19, added 1.5 inches of

polyiso (non reflective) over the north, east, and west walls.

So insulation levels now are:

- Lid -- 2 inches relfective

polyiso + 2 inches non reflective polyiso

- east, west, and north walls --

2 inch reflecticve polyiso + 1.5 inch non reflective polyiso

- bottom -- 2 inch non-reflective

polyiso + 2 inches extruded polystyrene

Collector inlet duct has 1 inch

polyiso + OSB + 1 inch polyiso

New Room Thermostat

The thermostat shown in the picture

above did not work. Since it was running the fan all the time, I just

unplugged the fan in the interium.

I replaced it with an electric

baseboard style thermostat. As of late Jan 19, its running with the fan

activated and the new thermostat.

Gary January 15, 2010