Search

The Renewable Energy site for Do-It-Yourselfers

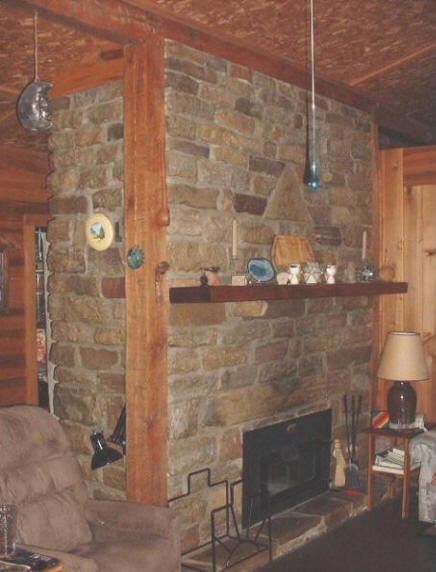

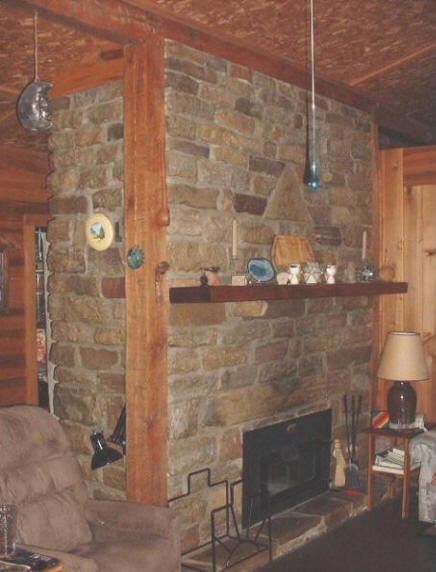

Doug's Masonry

Stove

My version of a masonry stove

Living for 10 cold New York winters

solely on wood heat made me want to learn more about wood burning stoves. I

studied and tried out several different designs. Airtight stoves appeared to be

the most efficient, but they are very smoky and inefficient when damped down to

hold a long, low fire for hours without tending.

The big lesson from cutting and splitting my own firewood for over 30 years:

anything I can do to minimize wood burning is a good thing! So, when I moved to

Tennessee, I built a passive solar, earth sheltered home described

here in Countryside Magazine and also

here ...

Because my house design works well, wood heat is now my only backup heat source,

and we burn only a small amount of wood yearly.

But during those cold times, extra heat is needed. I designed and built my own

version of a masonry heater (also called Russian masonry stoves, Finnish masonry

stoves, kachelofen in Germany), which was developed in cold northern climates.

These stoves are typically built with 20-30 tons of stone mass, thus holding

their heat for days.

Here in central Tennessee, where itıs rare to have extended cold, cloudy

periods, I want heat quickly, but not four days after I fire it. By designing an

air space between the firebox and stonework, along with room air vent openings

high and low in the stone surround, I get much faster warm-up than the

traditional masonry stove. Still I get the moderating and heat saving features

from the mass of the stone surround.

My stove also heats domestic water for my 85-gallon solar water tank in the

attic, which adds to the thermal mass for solar heat storage.

To improve the draft of the stove I

insulated the exterior of the masonry chimney. If you online search "masonry

stove," you find many expensive kits and plans explaining the basic theory of

masonry stoves. I used local, free stone that I gathered for the 3' deep x 9'

wide x 9' tall surround, which averages about 10" thick. Thatıs about 10-12 tons

of stone. Itıs on a 6" thick slab, poured separately from the house slab.

I welded up a firebox from scrap 1/4" and 3/8" steel, making an airtight door

with a tempered glass window in it. I ran 4" galvanized vent pipe from the attic

down through the surround, to the back of the firebox, and made a channel in the

concrete slab for the incoming air to flow under the fire to the front glass,

washing across the glass to keep it clean. Using air from the outside also

prevents the air needed for combustion from pulling replacement cold air in

around our homeıs weather-stripping on doors and windows.

I used 4 feet of 6" stainless steel exhaust stack from the firebox, which then

goes 2' over into a block-and-tile chimney. I coiled 30' of 3/4" copper tubing

around the vertical section of stack to heat water; it flows by gravity to my

solar tank located in the attic directly above it. The tank is supported by the

stone fireplace.

There is no damper, nor a thermostat to regulate the fire, so it burns hot and

cleanly. In 20+ years of use, I've not needed to clean the chimney yet.

The heat is soaked up into the stone and concrete. It takes about an hour for a

pulse of heat to travel an inch through stone, so we get a nice warming in back

of the fireplace after the fire itself is cooled to ashes.

With the solar house, we burn little wood, but I'm still glad I went for the

masonry stove. It is efficient, esthetically pleasing, and ends the typical

problem of either being too warm or too cold, as with a regular stove.

Doug

Jan 4, 2008

You can reach Doug at:

dougkalmer AT gmail DOT com (replace AT with @, and DOT with a period)

Doug's Other Projects

Doug has contributed a number of

projects to Build-It-Solar covering a wide range of solar and

renewable energy areas --

see them all...

Thanks very much to Doug for

providing this material!