Search

The Renewable Energy site for Do-It-Yourselfers

Thoughts on Mik's Stored Solar Heat

Cooking Scheme

Insulation

Mik points out the need for an inexpensive insulator that will hold up to the

high temperatures that the concentrator produces -- about 1800F.

The Engineering Toolbox provides this list of high temperature insulators:

http://www.engineeringtoolbox.com/insulation-temperatures-d_922.html

Mineral Wool is listed at 1800F. I don't know if this is the same

material that Mik used and had problems with, or whether this was fiberglass, or

perhaps used binders with a lower temperature capability?

It looks like Perlite might also be a candidate:

http://www.engineeringtoolbox.com/perlite-insulation-k-values-d_1173.html

Another approach might be to make the first layer of insulation something

like fire bricks (as in the type used to make kilns), and then surround this

with something like Mineral Wool. The temperature drop across the fire

brick would allow the Mineral Wool to run at a lower temperature.

It does seem like much better insulation would be a big plus as right now Mik

is able to heat the steel bars up to around 1500F, but can't put them in the

insulated barrel until they cool to about 900F -- so there is some heat being

wasted here that might be used if a higher temperature insulation could be

found? This might make the fire brick approach worth trying?

Solar Heat Input

The reflector has an area of 12.6 sf or 1.2 sm. For full sun, this

would be about (12.6 sf)(300 BTU/hr-sf)(0.9 reflectivity) = 3402 BTU/hr

To heat up the steel rods from 70F up to 1500F takes about (37lb)(0.12 BTU/lb-F)(1500F

- 70F) = 6400 BTU.

Mik reports that it takes a few hours to get the rods up to the 1500F or so

-- this indicates to me that the concentrator is getting the heat into the rod

bundle fairly efficiently, as it would take nearly two hours of good sun to get

the rods up to 1500F at 100% efficiency.

Heat Storage Material

Sensible Storage

Mik's setup stores heat as "sensible" heat using steel rods. Sensible

meaning that the heat that the material absorbs or releases as it changes

temperature.

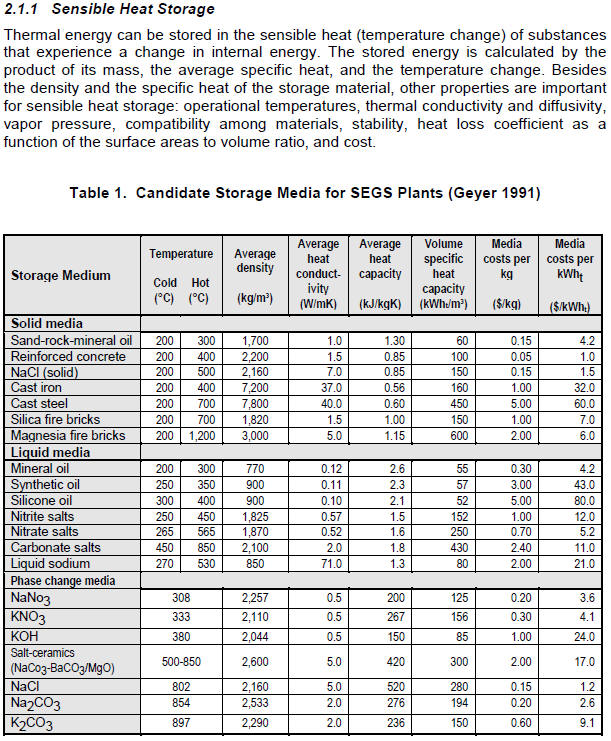

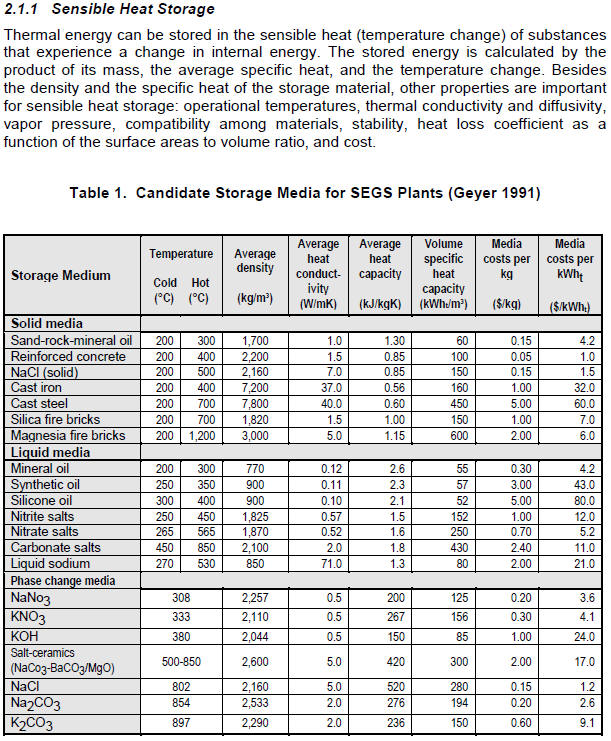

This is a excerpt from "Survey

of Thermal Storage for Parabolic Trough Power Plants", NREL

Looking over the list above of materials that might be used to store the

solar heat and also stand up to the high temperatures, the steel rods look about

as good as anything, and are readily available and cheap. But, there are a

few other materials that might be looked at -- e.g. Carbonate Salts? or Magnesia

fire bricks?

Using this sensible storage method, if the upper end of the usable

temperature range is is (say) 900F, and the lower end 250F, then each pound of

steel can store (0.12 BTU/lb-F)(1 lb)(900F - 250F) = 78 BTU. This

would be enough heat to warm one lb of water up 78F degrees if transferred with

100% efficiency.

The weight of Mik's steel rod bundle is about: (100

rods)(0.4*0.4in^2)(8 in)(0.285 lb/in^3) = 37 lbs.

So, the using the 250F to 900F range, the total storage is about (78 BTU/lb)(37lbs)

= 2900 BTU -- some of this would be lost with the less than 100% efficient

transfer to the food, but, it only takes about 1000 BTU to raise the temperature

of a gallon of stew from 70F up to 200F -- so, as Mik has already shown, that

there is enough heat here to do some useful cooking.

Latent or Phase Change Storage

Latent heat storage takes advantage of the fact that for most materials, it

takes a lot of energy to change the material from a solid to a liquid, and this

heat can be recovered at a later time. One advantage of this method is

that the temperature remains constant during the time that the material is being

converted from a liquid to a solid -- its basically a constant temperature heat

source. The downside would be that it would take a good

vessel to hold the molten phase change material and the safety issues for a

molten material seem more problematic.

Looking at the "Phase change media" section of the table above, it looks like

there are a couple salts that might be used (NaCl (table salt) or the "Salt

Ceramics").

Using the numbers in the table above for the best phase change material

(Salt-ceramics), it would take (2900 BTU)/(16.8 BTU/in^3) = 172 cubic inches of

he salt -- this is compared to 128 cubic inches of the steel that Mik used.

So, volume wise, its not as efficient as the steel . It appears that the

only real advantage would be the constant temperature as it releases heat.

The Cooking from Stored Heat

It seems like an insulating cooking pot would be worth using when possible --

this might make the stored heat last much longer.

Thermal cookware blog...

Hot box cooking... This might allow cooking two things at once from

the same stored heat source.

Gary

January 7, 2012