Search

The Renewable Energy site for Do-It-Yourselfers

Building the Solar

part of the Solar Dino

| The small solar electric system powers the dino horn and the

rotating dino beacon light. It has some reserve to power future

solar additions. Any ideas? The system consists of:

Two 15 watt, 16 volt PV panels hooked in parallel

A 12 volt lead acid battery (stolen from the lawn mower)

A small charge controller

12 VDC horn and 12 VDC rotating light

Wire, switches, fuse, horn button.

|

|

The solar panels and charge

controller were from a set I ordered from Costco sometimes back.

The 12 volt battery was stolen from

our lawn mower.

The horn is a an "oogah" horn from

Harbor Freight -- it does sound a lot like I would imagine a dinosaur to sound

-- I guess no one can prove me wrong on this :)

The rotating light is standard

rotating amber beacon made for trucks etc. as a caution light.

I thought that we could mount the PV

panels on the dino, but we could not find a large enough and safe enough place

to put them. So, we moved them a safe distance away and mounted them on

the ground.

The rest of the system is installed

up in the "drivers platform" behind a plywood panel. A wire runs

underground from the drivers platform to the PV panels.

In operation, the horn and light are

run off the battery, and the PV panel charges the battery through the charge

controller. The purpose of the charge controller is to prevent the PV

panels from overcharging the battery.

Two 15 watt PV panels should provide

about (15 watt*2)(4 hours) = 120 watt-hours of energy to the battery on a sunny

day. This is equivalent to (120 watt-hours)/(12 volts ) = 10 amp-hours a

day. So, this would run a 1 amp load for about 10 hours (or a 2 amp load

for about 5 hours, ...). In reality, the charging process and getting the

juice out of the battery process has some losses, so about 80% of these times

might be about right. Anyway, plenty for a horn and light used only a few

minutes a day.

The light is turned on with an

automotive toggle switch bought at an auto parts store.

I puzzled over the horn button for

some time. What I finally came up with is to use the "Dead End" dinosaur

sign that we had lying around. It is mounted with a hinge at the top, so

that it swings in and out. The horn button contacts are two short pieces

of copper pipe that are flattened -- one is mounted to the plywood bulkhead

behind the sign, and the other is mounted to the piece of plywood that the sign

is screwed to. When the sign is pushed toward the bulkhead, the two pieces

of copper come together and close the circuit to the horn. A small piece

of spony packing foam between the bulkhead and the sign keep the contacts apart

until you push the sign and compress the foam. A large head bolt through a

loose fitting hole in the bottom of the sign and into the bulkhead keeps the

sign from being pulled out more than a half inch or so, and protects small hands

from getting close to the contacts.

|

Pressing on the Dead End

sign sound the dino horn. |

The horn contacts are flattened

copper pipe sections soldered

to wires. The small piece of white

foam is the spring that keeps

the contacts normally separated. |

A fuse is used in the battery to horn

and light circuit to protect against short circuits. Even fairly small

lead acid batteries can provide quite a bit of energy on short circuits, so some

protection is important.

The PV panels come mounted on a very

flimsy PVC pipe frame. I decided to support these on treated wood 4X4's.

The vertical post with cross 2X4 supports the top end and lives in a concrete

footing. The bottom end of the panel screws to a 4X4 treated wood piece

that is staked into to the ground with angles 2 ft copper pipe. We get

some high winds, but these panels are not going anywhere.

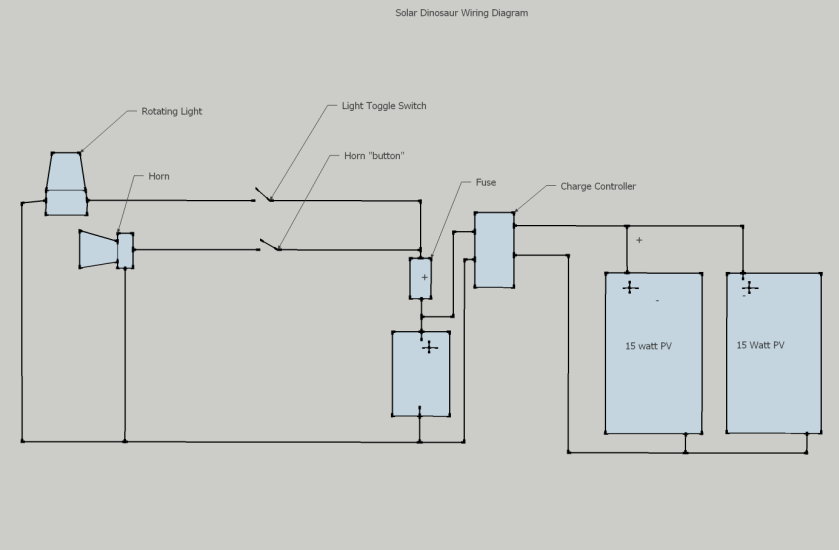

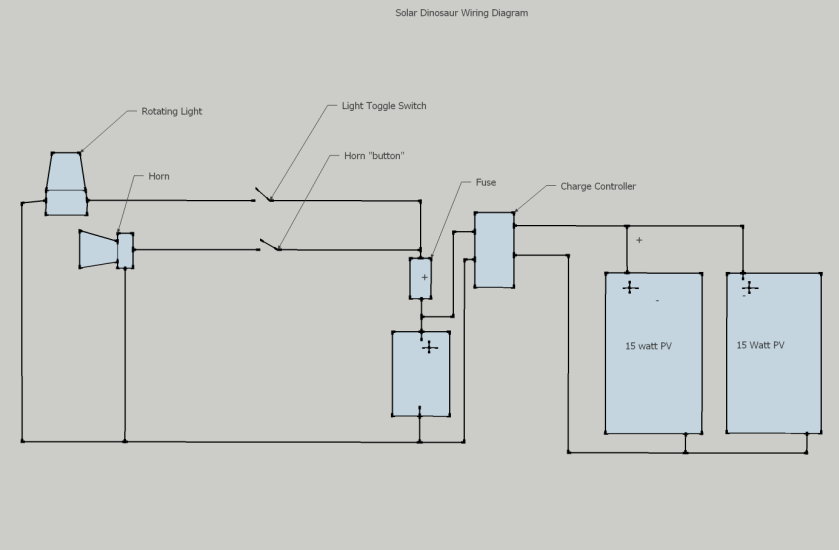

Wiring Diagram

Here is a rough wiring diagram for

the solar electric system.

I need to clean up the wiring a bit,

but is was functional for the first visit.

Gary September 5, 2009