Search

The Renewable Energy site for Do-It-Yourselfers

An Idea For a Simple, Cheap,

Efficient Pool Heater

|

Even though commercial solar pool

heating collectors are fairly inexpensive and work well, there seems to be a

strong interest in building collectors. The idea offered below for a

simple DIY solar pool collector could be built for about 1/4 the price of

commercial collectors, and (I believe) can perform roughly on par with

commercial collectors. Please bear in mind that the only thing that I have

actually built is a small 4 ft square prototype to test the idea (I don't have a

pool). So, if you build one for your pool you get to be a solar pioneer --

please let me know how it comes out.

On this page:

|

|

Overview:

This is an idea for a

potentially simple, cheap, durable, and efficient solar pool collector.

Comments are most welcome.

This solar pool heating collector

consists of a sheet of thin metal that is painted a dark color and sloped down

toward the south. The metal has channels or grooves that run from

top to bottom spaced closely. Water from the pool is pumped

to a manifold that runs along the top of the metal collector. The manifold

has a small hole above each groove that delivers a

small stream of water to the groove. The water flowing down the

grooves, picks up heat from the metal areas between the grooves. At

the bottom of the collector, the heated water is collected in a gutter like

arrangement that conveys the water back to the pool. The collector is not glazed.

The collector is similar to a

Thomason trickle collector, without the glazing.

The prototype collector I built

to test the idea is 0.02 inch thick aluminum soffit material that comes painted

in a dark brown. The grooves are preformed in the material by the

manufacturer. The individual panels are 12 ft long and about 16 inches

wide. The panels are pre-finished with what appears to be a durable

enamel, that will (hopefully) hold up to pool chemicals well. While this

collector works well, it appears from the testing that the efficiency

would be a few percent better with more closely spaced grooves. So, I think that

the wave style corrugated metal roofing may work even better (see test results below). I

used the aluminum soffit material because I had some around.

Potential advantages:

-

Its cheap -- maybe $1 per sqft

total (compared to $4+/sqft for commercial pool collectors)

-

Its efficient for the pool heating

application (see below)

-

Its easy to build

-

It should have a long life (but see

below)

-

Minimal maintenance and no freeze

problems

Not yet resolved issues:

You might well ask, how could a

solar collector that is not glazed and has open water channels that would allow

evaporative cooling be efficient?

-

The reason it can be unglazed and

still be efficient is the same reason that most commercial pool collectors are

unglazed. The pool water is usually lower in temperature or near the

same temperature as the ambient air -- this means that the

collector will lose little heat

to the air even without glazing. A further benefit of not glazing the

collector is eliminating the glazing solar transmission losses. This logic works in most climates during the swimming

season, but may not hold true in colder climates early or late in the season

-- in these cases a glazed collector may work better. This collector

could be glazed with polycarbonate (see tests below), but this increases the

price by another $1 per sqft.

-

The reason that the open flow

channels are not a serious evaporative cooling heat loss is that the channels are only about 10%

to 20%

of the area of the collector (see pictures) -- the rest of the collector

surface is dry. A calculation passed on by Nick Pine based on the ASHRAE

handbook estimates that the loss per sqft of water surface under typical

swimming season conditions is about 40 BTU/sqft. Since only 10% of the

collector surface is the water channels, this becomes (40 BTU/sqft-hr)(0.1

exposed) = 4 BTU/sqft-hr. This is a small loss compared to the incoming

solar radiation that is likely to be 250 to 300+ BTU/sqft-hr under sunny

conditions. This is further supported by the test results below for

glazed vs unglazed performance. The tests below indicate that the best

performance results from closely spaced water channels, even though this does

increase the water surface area a bit.

Prototype

Just to get an idea how well the

concept performs, I made a 4ft by 4ft test model from some left over aluminum

soffit material. See the pictures and captions below for the description.

Bear in mind that this was just to test the idea. A real collector would, of

course, need to be larger, and would need more permanent support structure

and manifold details.

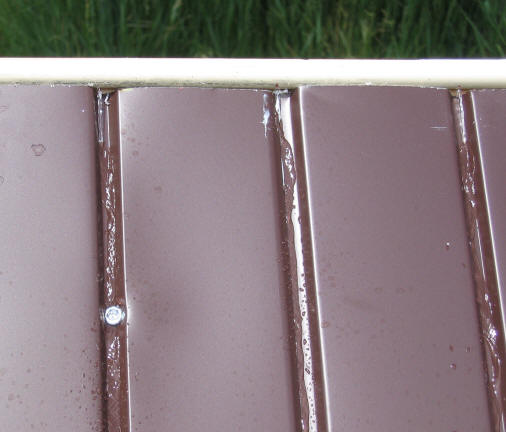

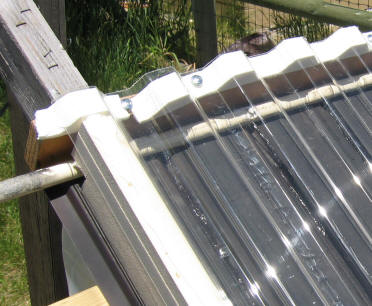

Prototype collector -- water is

pumped from the orange bucket (representing the pool) by a small submerged pump up to the

half inch CPVC pipe running along the top of the metal. This CPVC manifold

has a small hole drilled above each groove in the metal. Each hole

emits a small stream of water into the groove (the water is flowing in this

picture). The water flows to the bottom of the panel where the slotted PVC

pipe running along the bottom picks it up and returns it to the bucket.

Four versions were tested:

-

0.02 thick alum with channels/grooves spaced about

4 inches, water flow in channels only, no glazing

-

Same as 1 with corrugated polycarbonate

glazing added

-

Same as 1

with an additional set of manifold holes between each channel, which put out water

midway between each channel, no glazing.

-

Same as 3 with polycarbonate

glazing

The CPVC manifold distributing water

to each groove. There is a small hole in the manifold just above each

groove. The idea is to keep the water flow confined to the grooves as much

as possible to reduce water surface area and evaporation losses. This is

not a huge issue -- if water flows out over the metal between the grooves in a

few areas, its not a big deal.

Flow rate is about 0.7 gpm for the 14.25

sqft area.

Return flow from collector to bucket.

The submersible pump is sitting in the bottom of the bucket, and pumps water to

the top manifold via the clear plastic tube at the left.

Tests

I did some tests of the four versions

to estimate the efficiency.

The results:

| No |

Description |

Material |

Glazing |

Estimated Efficiency(1) |

| 1 |

Flow in channels, 4 inches apart |

0.02 alum |

None |

0.64 |

| 2 |

Flow in channels, 4 inches apart |

0.02 alum |

Polycarbonate |

0.63 |

| 3 |

Flow in and between channels |

0.02 alum |

None |

0.68 |

| 4 |

Flow in and between channels |

0.02 alum |

Polycarbonate |

(2) |

(1) The efficiency is evaluated when

(Tambient - (Tcolin - Tcolout)/2) = 0, that is where the average fluid

temperature going through the collector equals the ambient temperature.

(2) uncertain due to sun

fluctuations, but probably not as good as the unglazed version.

How the efficiency was estimated:

The test setup is shown in the

picture above. Water from the bucket is pumped by a small submersible pump

in the bucket to the top manifold on collector. Water is collected along

the bottom of the collector with the PVC pipe and returns to the bucket.

Each test started with the 5 gallons in the bucket at around 60F. As the

test progressed, the water in the bucket heated up. The tests were stopped

when then bucket water got into the 90F's. A logger logged the collector

inlet and outlet temperatures, the ambient temperature, and the solar intensity

throughout each test. The solar intensity was measured with an Apogee

Pyranometer. The flow rate was about 0.7 gpm, or about 0.05 gpm per sqft

of collector. See sample plot below.

The efficiency is:

Efic = (Heat to

Pool) / (Solar Radiation Incident on Collector)

The Heat to Pool was calculated as:

Heat to Pool = (Tcolout

- Tcolin) (Flow Rate) (specific heat of water) BTU/hr

Where Tcolout is the collector outlet

temperature, Tcolin is the collector inlet temperature, and flow rate is the

water flow rate in lbs per hour. Specific heat is the specific heat of

water = 1 BTU/lb-F.

Solar Radiation Incident on Collector

was measured directly using an

Apogee Pyranometer.

The 68% efficiency compares to an

average of around 80% efficiency for the commercial collectors that the

SRCC has tested.

There are no doubt differences between the SRCC methods and mine, so I would use

this as a very rough guide only. This collector might be a few percent

less efficient than a commercial collector, but is only about 1/4 the cost --

quite a good bargain in BTU per dollar spent.

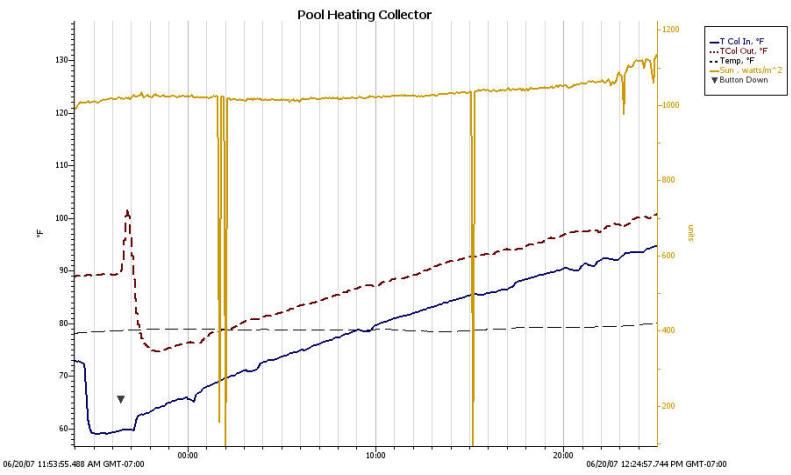

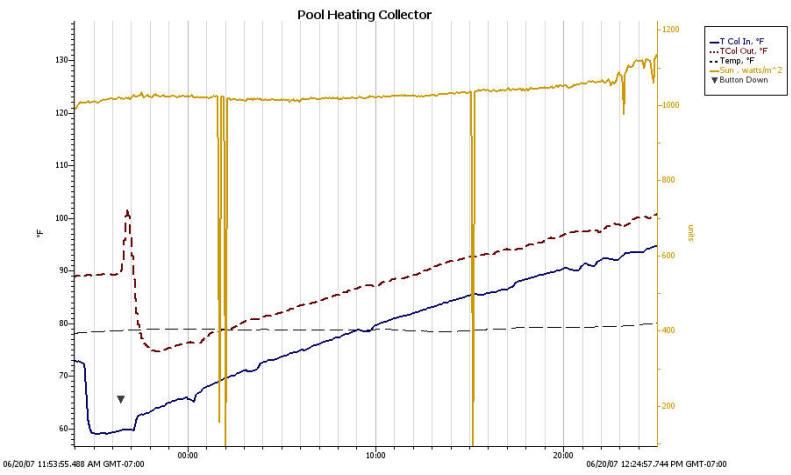

Test plot for configuration 2.

The pool (bucket) water starts around 58F and gets heated to about 95F by the

end of test. Note that the the difference between the collector outlet and

inlet temperature decreases as the water in the bucket warms up -- this is

because the collector losses increase as the water

circulating through the collector gets warmer -- this causes a drop in

efficiency.

The efficiency is evaluated

at the point where the average collector water temperature is equal to the

ambient air temperature -- about 5 minute point on this plot. The grey line is

ambient temperature.

The big drops in solar intensity at a

few points are me shadowing the Pyranometer.

The relative humidity was not

measured, but was likely around 20% -- possibly lower.

Some additional descriptions and

pictures of the configurations tested:

Configuration 1:

0.02 thick alum with channels/grooves spaced about

4 inches, water flow in channels only, no glazing.

|

|

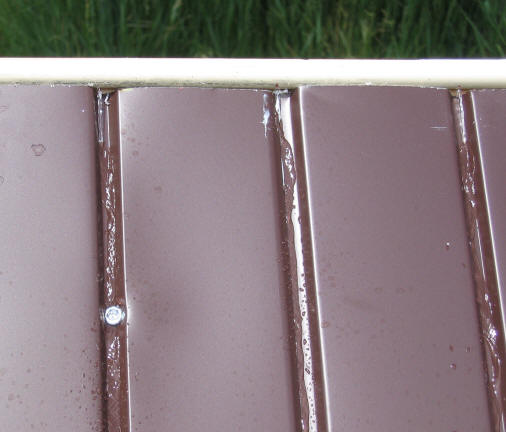

This is 0.02 thick aluminum roof

soffit material with preformed channels spaced every 4 inches. The panels

are 16 inches wide. Multiple panels can be joined together via a joint

that is preformed in the edge of the material -- silicone should be applied in

the joint groove before joining pieces to prevent leaks. The right picture shows the

half inch CPVC pipe spraying a little water into each groove. Spraying the

water only into the groove reduces the open water area and associated

evaporative losses. Typically the surface temperature measured half way

between the grooves is about 15F higher than the temperature at the groove --

indicating that heat loss to the air would be lower if the grooves could be

spaced closer together to reduce the temperature midway between grooves -- see

configuration 3. The water flow rate is 0.05 gpm per sqft of collector.

With this flow rate, the water gains about 10F to 15F as it flows down the

channel. If the flow rate were increased a bit, the temperature rise from

the top of the panel to the bottom would be reduced, and the efficiency of the

panel increased (due to lower heat loss from the cooler absorber). If the

idea that cooler outlet temperatures can make the panel more efficient seems

strange, look here.

Configuration 2:

0.02 thick alum with channels/grooves spaced about

4 inches, water flow in channels only. Corrugated polycarbonate glazing.

This is the same as Configuration 1

except that SunTuf corrugated polycarbonate glazing has bee added over the

absorber to see if the glazing improved efficiency by reducing absorber heat

loss and reducing evaporative cooling from the open water channels. It

turned out that the performance was just about the same as the unglazed version

-- this is probably due to the solar transmission losses of the glazing

offsetting the other gains.

Configuration 3:

Same as 1

with an additional set of manifold holes between each channel, which put out water

midway between each channel, no glazing.

This is the same as Configuration 1

with an extra set of holes drilled in the manifold midway between the grooves.

This was to try and see if having the grooves closer together would result in

better heat transfer from the aluminum to the water, and if this would be enough

to offset the greater evaporative losses from more exposed water surface.

This did result in a significant improvement in performance, and would probably

have done even better if there had actually been another set of grooves instead

of just letting the water flow randomly over the fin surface. Based on

this, I would be inclined to say that the wave style corrugated roofing material

with the corrugation valleys spaced closer together would perform better than

this soffit material with the grooves spaced at 4 inches.

| |

Note that

the streams between the grooves tend to wander around, and sometimes

just divert over to an adjacent groove. Solar Mike from NZ

suggested that applying a bead of silicone down the metal where you want

the water to go. Mike says that the water will follow the silicone

bead very nicely. This would allow using flat metal

sheets with no grooves at all. Thanks Mike!

|

Configuration 4:

Same as 3 with polycarbonate glazing

This is the same as Configuration 3,

but with corrugated polycarbonate glazing added over the absorber. This

tested to a lower efficiency than Configuration 3, but there was some variation

in sun intensity due to some high clouds coming, so I am not showing an

efficiency number.

Heating

Performance:

Here is a rough cut at how much heat

output you might get from this kind of collector, and how much it might warm up

a typical pool.

A 16 ft diameter round pool has an

water surface area of 200 sqft (Pi*8^2). If it is 3 ft deep, then it has a

volume of (200 ft^2)(3 ft) = 600 ft^3, or about 37000 lbs of water.

A collector with an area of one half

of the pool surface area would be 100 sqft.

Using the 68% efficiency from the

test above, this 100 sqft collector might collect about:

Qcollector = (100

sqft)(2200 BTU/sqft-day)(0.68 efic) = 150000 BTU/day

Where 2200 BTU/sqft-day is typical

sunny day radiation on one sqft of collector for one full summer day.

If all this heat went into warming

the pool, it would increase its temperature by:

dT pool = ((150000

BTU/day)/(37000 lbs) (1 BTU/lb-F) ) = 4 F in a day

But, not all the heat goes into

increasing the temperature of the pool water -- some goes into offsetting the

pool heat losses. You can minimize the losses by using a pool cover.

Since most of the pool heat loss is from the surface of the water, the pool

cover might cut the pool heat loss in half. If the pool is in the sun,

then a solar pool cover will collector additional solar heat during the day.

The 150000 BTU from the collector is

equivalent to burning 2 gallons of propane (worth about $4 around here) in an

82% efficient heater. This gives a payback of about one month if you

can build the collector for a bit over $1 per sqft.

Construction thoughts:

I don't have a pool, and I

built this small prototype just to see if the idea works. If you plan to do a

full sized collector to heat an actual pool, here are some thoughts on the construction --

based on no real

experience whatever.

The metal soffiting or roofing that

is used for the collector absorber will

need to be supported along the top and bottom, and probably at intervals along

its span. A simple rack from treated lumber with horizontal purlins to

support the metal panel would be one way to go. It might also be possible to

use an existing fence, building, or roof for part of the support. When

setting up the support structure, bear in mind that the top manifold must be

very near level, and the bottom gutter must slope down slightly to the

collection sump. The joints at the edges of the roofing or soffit panels

may require sealing with silicone to prevent leaking.

You can use one of the calculators on

the pool page to estimate the size of the

collector you need to heat your pool. A very, very rough rule of thumb is

that the collectors should be half the surface area of the pool -- about 100 sqft

for a 16 ft diameter round pool. Remember that a pool cover is a must to

reduce heat loss.

The collectors should ideally be

tilted at an angle that is approximately your latitude minus 15 degrees.

So, if you live at 40 degrees latitude, an ideal tilt would be about 25 degrees.

The tilt angle is not critical. Tilts anywhere from near 0 degrees (flat)

up to an angle equal to your latitude will give good solar performance. You

do need enough tilt to make the water flow down the panel. The

panels should ideally face south, but anywhere between SE and SW is fine,

especially for panels with a low tilt -- even low tilt panels facing east or

west would probably be OK. The panels should be

positioned where they will be in sun at least 6 hours a day. If you are at

all in doubt about things that may block the sun, then do this

solar site survey.

I would pay careful attention to

protecting the metal from rust and corrosion. The pre-finished paint job

the panels come with should be durable, but anyplace you drill holes or cut the

sheets should be protected.

The manifold along the top of the

collector is quite sensitive to tilt. I would drill all the water

distribution holes, then clamp the manifold in place so it level. Then

hook up the pump to the manifold, and make sure the water is coming equally out

all the holes -- if not, adjust the manifold tilt until you get an even

distribution -- then permanently fasten it. Long manifolds should probably

be fed from the middle, or, maybe even at multiple points.

The gutter along the bottom needs to

have a slope toward the sump -- maybe 1/8 inch per foot?

I would test the flow with a garden

hose before permanently attaching it.

The gutter could be a 2 or 3 inch

diameter PVC pipe with a slot cut in it that is just wide enough to allow the

metal to fit into it. This is probably better than

an open gutter from the standpoint of reducing evaporation heat losses.

The gutter in the prototype pictures is made this way. When building the

support structure, remember that half of the diameter of the gutter is on each

side of the plane of the sheet, so the gutter support will need to be set back a

bit.

If the pool pump is used to circulate

water through the collector, then a way needs to be worked out to get the pool

pump to pick up water from the collector sump. This may

involve installing a check valve in the line from the sump to the pump intake

line to insure that the pool does not drain into the collector sump? I

don't know much about pool pumps -- if someone knows a good way to do this,

please let me know.

The pool pump also needs enough

pumping head capability to lift the water to the collector manifold -- most pool

pumps should be OK for this.

If the bottom of the collector can be

placed above the pool surface level, then no return sump is needed, the water

from the gutter can just be piped back to the pool by gravity flow.

You could also use a small dedicated

pump to circulate water through the collectors independently of the pool pump.

It should be rated at about 0.05 gpm per sqft of your collector area -- so, 5gpm

for a 100 sqft collector. It should be rated to produce this flow at a

head of at least the vertical distance between your pool water surface and the

manifold -- allowing for some extra head to overcome pipe resistance is a

good idea.

In any case, you need to have some

means to insure that water is not circulated through the collectors when the sun

is not shinning on them, or you will end up with a pool cooler instead of a pool

heater. A timer might do this if your weather is

consistently sunny during the swimming season. A differential controller

would be even better, but adds some expense and complication.

If you build one of these please let

me know how it all goes --

Gary.

Matt has done a really nice job of building and documenting a

collector based on this design:

Its done with corrugated metal roofing as the trickle down absorber.

Its nicely integrated with the pool, and uses a solar powered pump, so

there is no power use at all.

The 64 sqft collector heats his 25 ft diameter in ground pool nicely.

Cost of the collector along worked out to only $1.80 per sqft.

Matt's Open Flow Solar

Pool Heating Collector... |

Alternative DIY Collectors:

There are some other potential

homemade collector designs listed here in

the "Homemade Pool Heaters" and the "Something Else to Try?" sections.

Of these, the coil of black plastic

pipe is by far the most common. I think that these pipe coil collectors

can work, but it will probably require a lot of pipe to work well. If you

take the sample 100 sqft collector mentioned above, it would take a length of 1

inch outside diameter pipe of about 1200 ft long to have the same 100 sqft

exposed area. This is certainly possible, and I have seen pictures of

collectors which appeared to have something of this order laid out.

It does take a fair amount of space. The cost might be around $2.50 per

sqft. Its a nice simple design that might be well suited to some

situations. If anyone has experience with this type of collector or has

taken some performance measurements, please let me know --

Gary.

I saw a picture of one pool collector

that consisted of a piece of black poly film laid out on a slope just above the

pool and extending to the pool edge. A hose delivered water from the pool

to the top of the plastic film, and the water ran down the film picking up heat

from the black poly and then drained back into the pool. I am

guessing that this actually worked fairly well if the water was distributed

evenly over the film -- this is how simple pool collectors can be :)

The pipe coil pool collectors shown

at the right are some pictures found on the Internet with no real explanation.

Gary 6/17/2007