Search

The Renewable Energy site for Do-It-Yourselfers

Solar Experimentation Thing in MT

Basics

Pictures below show the small solar greenhouse and solar experimentation

building.

It is 20 by 10 ft (20 ft in the E-W direction) .

Glazing is also 10 by 20 ft slopped at 60 degrees -- 10 mm twinwall

polycarbonate.

It modeled roughly after this GH, but smaller.

Floor has vertical perimeter insulation down to 2 ft, and 1.5 inches of EPS

will be used in the floor.

Walls and north roof are 2 by 6, and will probably insulated with R21

fiberglass plus 1 inch polyiso rigid board inside for about R28 with good

protection against thermal bridging.

I am taking some pains to reduce air infiltration with careful sealing and

construction adhesive.

Insulated door.

Two 10 inch fans in the peak provide for exporting heated air when its being

use to test how much heat it could provide to an attached house (if it was

attached to a house :)

Three Phase Learning Sequence

This is eventually intended to be a greenhouse that can be used through most

(or all) of the winter, but I'd like to try a couple other things first:

Phase 1: As a house heating sunspace. (this

phase is well along -- see the details and test results here...)

I'd like to complete the structure including insulation

and sealing, and then use it to experimentally measure its heat output as if it

were a sunspace attached to a house. I like the idea of using a

low

thermal mass sunspace to provide heat to an attached house, and would like to

use this GH to validate the calculations that show that a sunspace can be an

efficient and cost effective heating structure (as well as serving some

additional valuable functions). That as a sunspace it can be as (or more)

efficient than active solar heating collectors.

One problem with this is that I don't have a good supply of room temperature are

to replace the heated air that I take out of the sunspace -- any ideas on this?

One possibility would be to run a large duct over to the shop to act as an inlet

air source?

Another problem is that I need a way to keep the direct solar coming in through

the glazing from being absorbed by the floor -- some kind of cheap insulating

layer I can put on the floor for this part of the testing?

Phase 2: A thermally self-sufficient tiny demo house (does not look

like this is going to get done this year)

This is basically an extension of this

Barra box

experiment -- idea is to convert a part of the GH (probably the West 8 ft)

into a small, livable room that maintains its temperature at "comfortable"

levels just using solar heat input.

I don't have any firm idea what this design should be, so

any ideas would be welcome.

One thing that occurred to me during the building is that

if the size of the whole thing was increased a bit (maybe 12 by 24 ft?) that

this would make an interesting

Tiny House plus attached sunspace/greenhouse arrangement. The Tiny

House could occupy the east or west end and be thermally efficient. The

sunspace/greenhouse would provide the ability to be more self-sufficient by

growing vegetables and it would also provide some additional sunny living space

when the Tiny House feels too tiny.

I guess this version would not have to be totally thermally self-sufficient with

only solar heat, but could aim to have a yearly heating bill of (say) $100?

Phase 3: A solar greenhouse

The end goal will be a greenhouse that can grow things

through the Montana winter.

The GH as it is is based loosely on this

Univ of Missouri GH which in the Missouri climate is able to grow all winter

with no supplementary heat.

In MT, this will probably require some additional work -- perhaps movable

insulation on the glazing? Any ideas?

Any thoughts or suggestions on any of the phases would be appreciated -- see

Comments section below.

Foundation with perimeter vertical ground EPS insulation that goes down 2 ft and

is 1.5 inches thick -- its 10 by 20 ft and the 20 ft side faces south.

The plan is to add 1.5 inches of EPS floor insulation followed by a little pea

gravel and pavers.

The front knee wall -- I tried to pay attention to air sealing -- thus the

construction adhesive between sill plate and foundation board.

South and north walls -- both 2 by 6 with single plates.

Most of the framework.

Fitting the front glazing frames. The glazed area is 20 ft wide by 10

ft high twinwall polycarb. Framed at 4 ft intervals to try to minimize the

shading from framing.

Another view of the framing.

Applying the glazing -- five sheets of 10 mm 4 ft by 10 ft twinwall polycarb.

Finished the glazing during the first snowstorm of the year.

Inside -- I think that all those bright white spots are snow flakes

falling in front of the camera?

Stagnated Sunspace Test

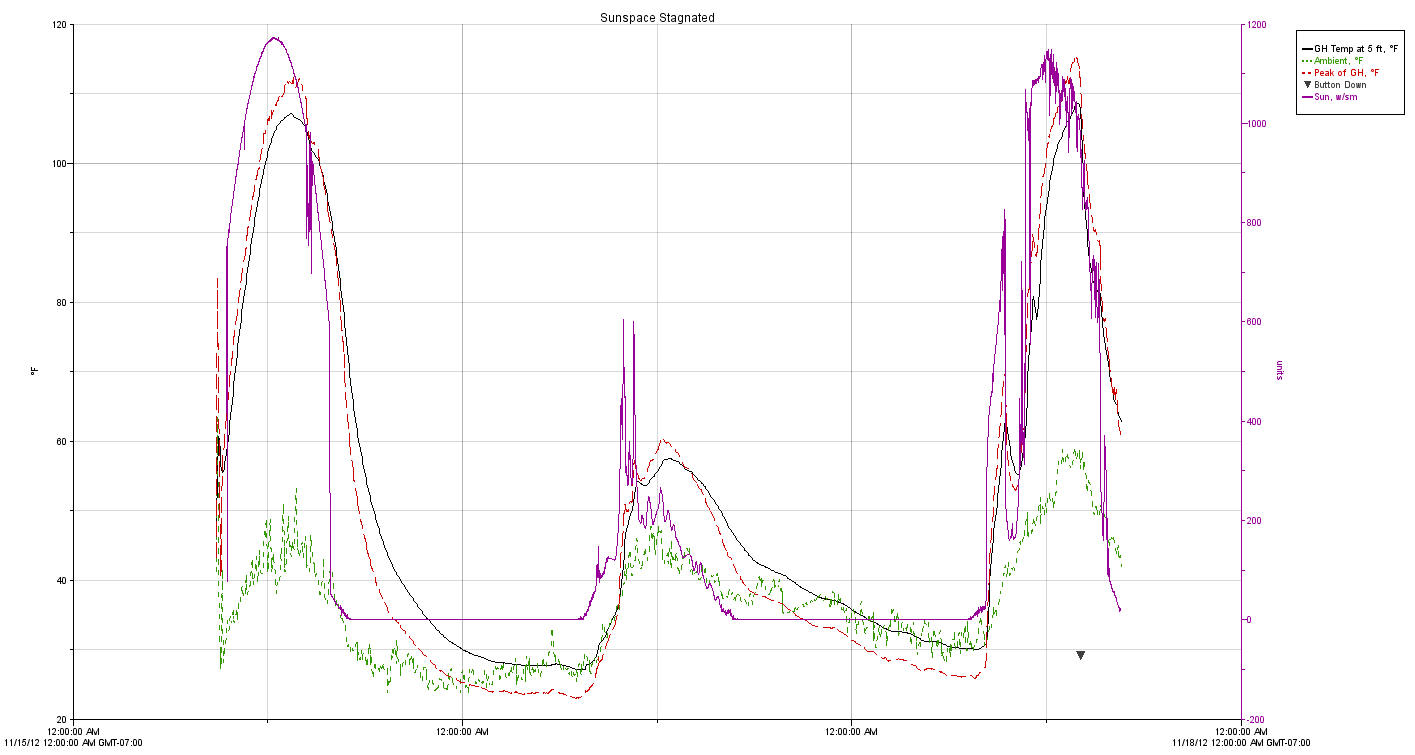

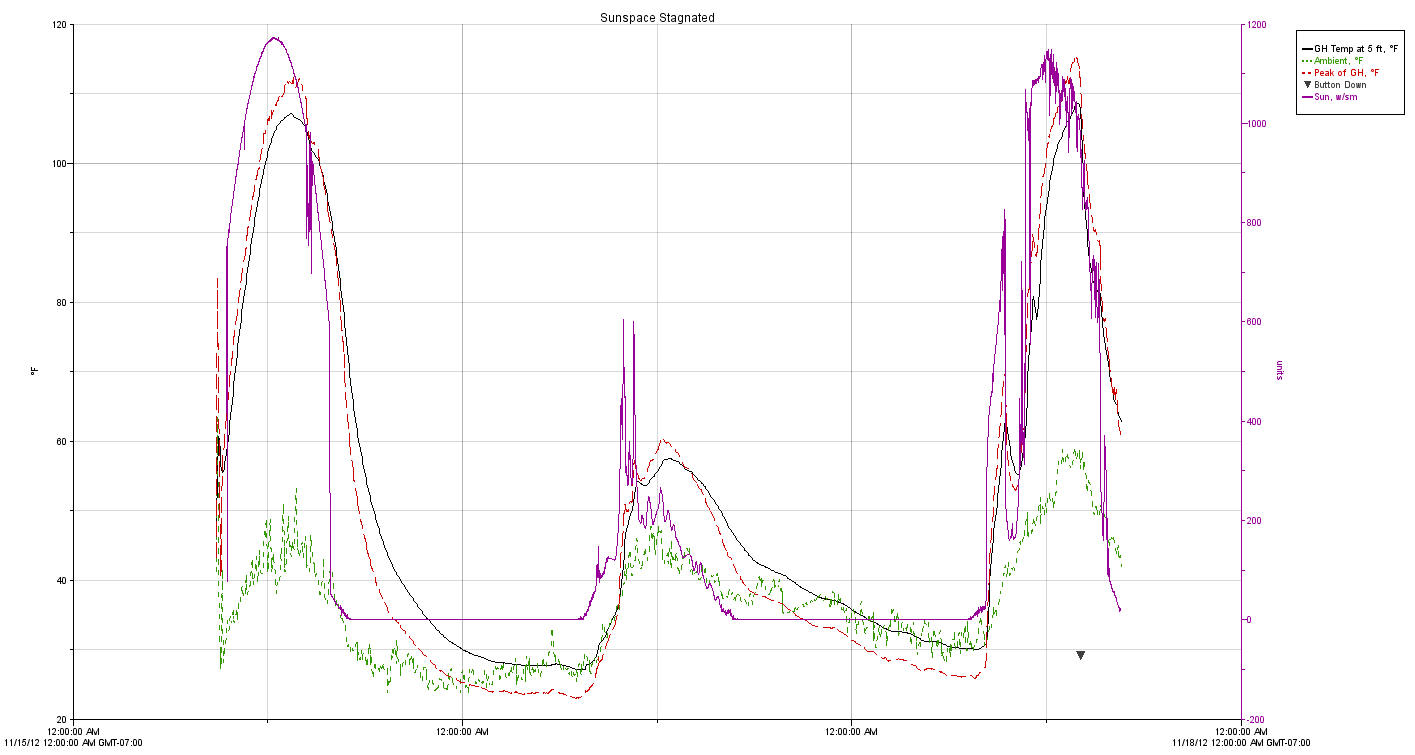

The plot below shows the GH/sunspace stagnated for its first 3 days of

operation after first being closed in.

The first and last days were sunny, and the middle day was very little sun.

The status of the GH was:

- Closed in and well sealed up -- infiltration should be small

- Dirt floor -- no floor insulation other than the vertical perimeter

insulation.

- No wall or ceiling insulation.

- Air heated by the GH was not removed -- it was stagnated.

On the plot:

purple trace is sun in watt/sm

Green trace is outdoor ambient temperature (taken on

north wall of GH about 6 inches of the wall at 5 ft high)

Red trace is a temperature sensor located near the peak

of the GH.

Black trace is temperature at the logger unit on

west wall about 5 ft off floor.

The peak temperature got up to near 120F on both of the two sunny days, and

temp at 5 ft off floor was not much less.

Temperatures fall fast when sun goes off the space.

Sun level on middle day was low, but still produced some warming above

ambient. A conventional active solar collector would never have

started up on this day, but the sunspace is still able to get a little heat --

although not enough to be useful for home heating.

Go on to see the testing of the low mass

sunspace version...

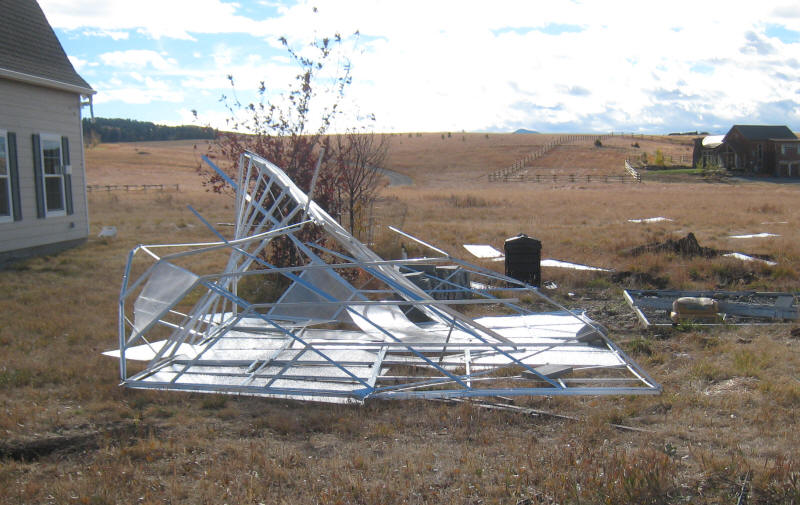

The earlier version -- lesson: don't use a kit Harbor Freight GH in an area

that gets occasional high winds :)

Gary

November 9, 2012