| |

Solar kilns come in two main configurations;

- Solar kiln - Where the kiln design relies on the glasshouse

principle. It traps light energy as heat when it passes through the

cladding. External solar collectors are not required

(Palmer & Kleinschmidt 1992).

An example of this type is used by the

Queensland Forestry Service (see figure below), where they use a roof

and three walls of the kiln clad with polycarbonate sheeting that has been

fixed to a timber frame, and sealed with silicone sealant and corrugated

foam infills. The rear southern wall is lined with both timber on both

sides, and the cavity is filled with polystyrene foam. Loss of heat to the

ground is restricted by a timber floor in the plenum and concrete in the

stack chamber. A reversible fan, 1.1 m in diameter and driven by a 1.5 kW

motor, provides air circulation and about one metre per second through the

stack. The design uses screens to form a drying room within an outer

chamber, so that air can circulate horizontally through the timber stack.

Total cost of constructing a kiln of 15 cubic metres capacity in December

1990 was $15 000

(Palmer & Kleinschmidt 1992).

A view of the QLD Forestry solar kiln from the north west.

(Palmer & Kleinschmidt 1992)

A view of the QLD Forestry solar kiln from the south west.

(Palmer & Kleinschmidt 1992)

- Solar Powered Kilns - Where the kiln design relies on solar

collectors and heat exchangers to transfer the heat energy to the stack of

timber.

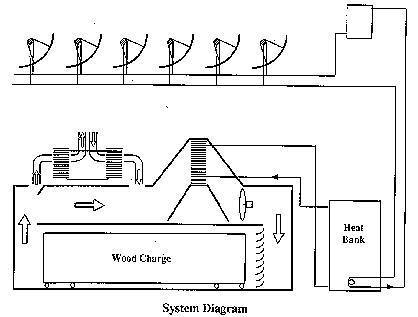

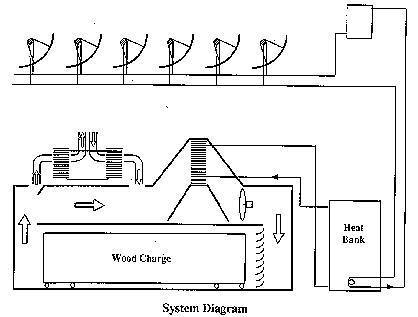

An example of this type was designed by staff of the

Australian National University (see figure below). The solar

collectors are fabricated from sheet metal and have been designed for easy

manufacture. The troughs are glazed with mirror strips. The troughs

currently operate at atmospheric pressure and can heat water to over 90

degrees centigrade. The troughs heat water in the collectors which are

then used to heat water in a storage tank. This tank is a "heat bank" to

store energy for use during the day and well into the night. This heated

water is then passed through heat exchangers, to heat the air in the

drying chamber. Temperature and humidity are regulated by a logic

controlled vent system.

A new solar powered kiln designed at the Australian National University

Trough and collector.

|